Lingering odours coming from your industrial or commercial facility can be a problem not just due to nuisance smells, but also a sign that a threat of contamination is present or that your facility could be emitting hazardous gases into the environment. Masking agents and ventilation may alleviate the nuisance to some extent, but they are not an adequate solution. The best solution is to eliminate odours at the source. Finding the culprit and matching it with the right molecular filtration solution can be a challenging task. This article will detail the various options for true odour control, which involves removing odour-causing molecules from the air, and explain how molecular filtration works.

What Makes an Odour? The Chemistry of Unpleasant Smells

Odours don’t stem from bad air, but come from certain offending airbourne molecules. Gases such as methane, formaldehyde, Volatile Organic Compounds (VOCs), ammonia, and hydrogen sulfide (H2S) can be quite difficult to remove from the air using traditional carbon filters. More robust solutions are needed. High-MERV-rated and HEPA filters are not effective for odour removal because, although they are engineered for fine particle removal, they do not remove much smaller gaseous molecules. A more robust solution is required.

VOCs become gases at room temperature. Many odours, both pleasant, such as aromatic essential oils, and unpleasant, like those produced by mould that create mVOCs, originate from natural and man-made sources.

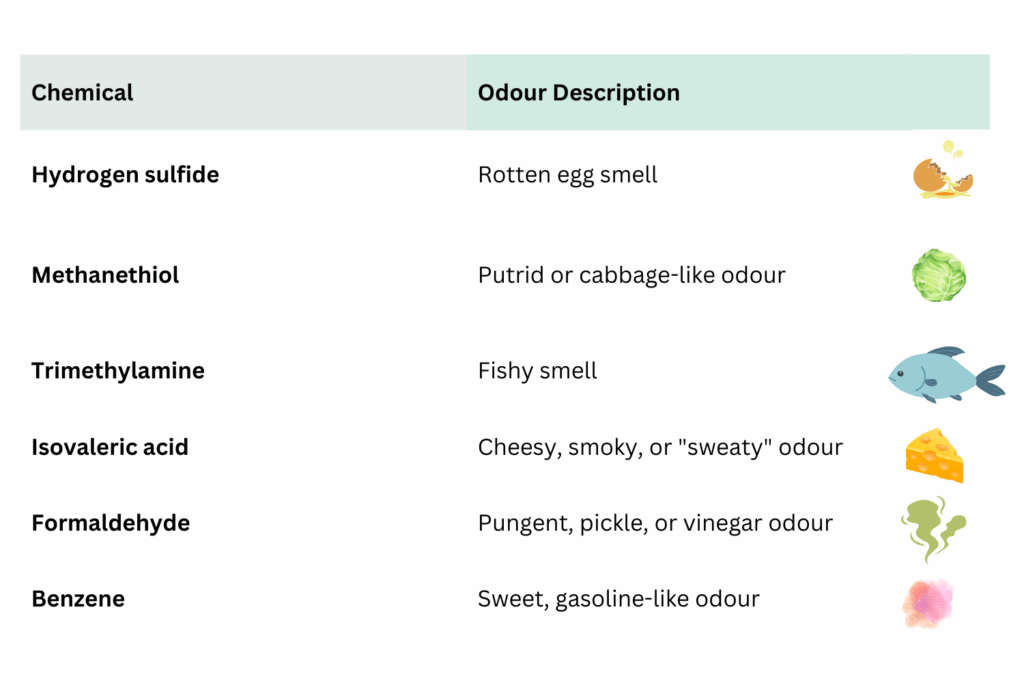

Examples of odour-causing gases/VOCs :

Health Canada Guidance on Odour

Health Canada states in its new publication “Guidance on Improving Indoor Air Quality in Office Buildings 2025, “Odours (smells) can be indicative of elevated levels of certain contaminants in indoor air, which may lead to potential health risks. Of note, the health effects of some indoor contaminants are recognized to occur at levels below the odour threshold. Odours are associated with a perception of poor air quality, regardless of whether or not the source of the odour is a nuisance concern (e.g., food odours) or has the potential to result in direct health effects (e.g., vehicle exhaust). Odours are caused by organic or inorganic gases and vapours that stimulate the olfactory organs.”

The Limitations of Traditional Odour Control Methods

Masking agents

Masking agents are often used to mitigate offending smells, but they contain VOCs and can be harmful to human health, especially to those who have preexisting conditions like asthma. It’s essential to note that masking agents do not eliminate the source of the smell; they simply add a different scent to mask it, and foul odours can still be present.

Ventilation

Ventilation is crucial for clean air indoors, but it only dilutes odours; it doesn’t eliminate the molecules that cause the odours. Additionally, increasing ventilation rates can be costly for your facilities in terms of the energy consumption required to eliminate foul odours.

Ozone Generators

The Connecticut Department of Public Health and the Canadian Government state that ozone generators are not a safe or effective way to control odours. They also create harmful byproducts that can lead to respiratory irritation. The high levels of ozone required for odour control can actually worsen indoor air quality by reacting with household chemicals, producing toxic substances such as formaldehyde.

Dealing with Acid Gases

Each acid gas has its own odour. For example, the rotten-egg smell of hydrogen sulphide (H2S) and the pungent odour of sulphur dioxide (SO2) are distinct. Hydrochloric acid (HCl) and acetic acid have their own often unpleasant smells, such as vinegar or a pungent, irritating odour. This variety in odours often requires different solutions for odour and contamination control.

The Molecular Solution: The Technology Behind True Odour Removal

How Adsorption Works

Molecular filtration, AKA gas-phase or chemical filtration, unlike particle filtration, does not simply physically trap the contaminant; it involves a process whereby a substance, such as activated carbon or activated alumina, sticks to the contaminant through physical and chemical interactions in the very high surface areas of an advanced molecular filter. The molecules (from gases, vapours, and odours) are attracted to the porous substance, and adsorption occurs. Adsorption ensures the removal of odorous or hazardous molecules, resulting in high-quality air. Some filter media are impregnated to properly target VOCs, acids, and odorous gases.

How Does Chemical Adsorption (Chemisorption) Work?

Select Camfil molecular filters are chemically impregnated to create a stronger chemical bond with certain gas molecules that are more difficult to remove, such as potassium hydroxide (eg, KOH, an inorganic compound). This process is called “Chemisportion.”

Ion Exchange Resins

Filters, such as the GigaPleat®, can be filled with ion exchange resins that chemically react with certain gaseous pollutants in the air. This approach differs from simple adsorption. It involves swapping gaseous pollutants with ions from other sources.

Molecular Filtration Product Types:

Box Type Filters: Pleated or loose-filled, suitable for installation in front or side-access housings in commercial HVAC systems.

Cylindrical Canisters: For high gas and vapour loads in HVAC systems, filled with specially formulated activated carbon or activated alumina.

Panel Filters: Loose-filled options for specific gases and odours.

Combination Filters: Integrated particle filtration and molecular adsorption for dual protection.

Specialized Products: CamCarb cylinders and CamPure media provide tailored adsorption for targeted contaminants such as VOCs, formaldehyde, ozone, and acids.

Applications and Performance

Camfil’s molecular filtration solutions are essential for ensuring clean and safe spaces in hospitals, laboratories, data centres, food processing facilities, and manufacturing facilities. Filters are rigorously tested against top standards, such as ISO 10121 and ASHRAE 145.2, ensuring they effectively handle specific gases in all situations, from daily use to critical use applications.

Product Features of High-quality Molecular Filters

Advanced molecular filtration solutions utilize the latest technologies and filter media for efficient removal of a wide spectrum of harmful molecules from indoor air, supporting safety, compliance, and operational reliability. This is all achieved with the added advantage of the longest service life in the industry.

Camfil’s Activated Carbon Solutions

Broad-Spectrum Carbons

Broad-Spectrum Carbons can capture a wide range of odour-causing molecules. For molecular filtration solutions, it is most effective when the specific chemical mix being targeted is unknown or complex, such as for industrial kitchens or industrial processes.

Impregnated Activated Carbons

When the chemical mix has been identified and is consistent, or when dealing with more challenging odours, Camfil offers specialized carbons that are chemically treated to adsorb acid gases, ammonia, or other compounds.

Key Benefits of Molecular Filtration for Odour Control:

- Odour Elimination: Effectively removes the source of odours rather than merely masking them.

- Equipment and Health Protection: Molecular filters not only prevent the corrosion of sensitive electronics and equipment but also safeguard individuals from harmful gases.

- Energy Efficiency: Pre and post-filters enhance airflow through the filtration media while capturing any dust generated during the molecular filtration process.

- Broad Spectrum of Use: These filters can be customized to target a wide range of specific gases.

Applications for Which Molecular Filtration is a Must

Wastewater Treatment Plants: Releases of hydrogen sulfide (H2S) and other gases are a widespread problem for wastewater treatment plants. Proper molecular filtration protects workers and prevents the “rotten egg smell” from affecting the nearby environment.

Pulp and Paper Mills: Molecular filtration controls sulfur-based compounds from the highly acidic processes of producing bleached kraft paper and other processes. Chlorine gas, H2S and lime dust must be controlled.

Food and Beverage Manufacturing: Dairy processing plants, fermentation plants, and breweries can utilize filtration to remove specific odours from their facilities, maintain product quality, and improve their environments.

Commercial Buildings & Data Centres: Molecular filtration protects electronic equipment from corrosive gases while eliminating chemicals that stem from vehicle exhaust.

Indoor Cultivation Facilities: Chemicals are released into the nearby environment from indoor cannabis cultivation plants. To prevent the release of terpenes, which cause odours, molecular filters must be used to remove the strong and specific odours associated with cannabis production facilities, thereby preventing public nuisance.

Oil & Gas: Refineries require molecular filtration media for corrosion control and health and safety purposes, while upgraders utilize molecular media to refine their gas streams.

Biogas: RNG plants utilize molecular media, such as CamPure 32, to remove H2S from their gas stream, refining it and protecting the upgrader system that typically follows this filtration stage.

Examples of Successful Solutions, from Camfil Molecular Filtration Specialist Geordon Hoag

Geordon Hoag recently introduced solutions for a wastewater management project, highlighting the transition from using two types of media for odour control to the Campure 15 (CEX004A3) impregnated carbon solution. This new solution can be expected to last 15-25% longer, which will help extend the purchase cycle and alleviate labour shortages related to maintenance.

Also, Hoag states, “A city in British Columbia was previously using two media types for odour control. I recommended Campure 15, which captures more sulfur and provides a longer-lasting media to absorb hydrogen sulfide (H2S) and volatile organic compounds (VOCs). This change is anticipated to result in increased efficiency through improved media performance, backed by enhanced lab testing, ultimately creating a stronger and better solution for odour control.”

The Future of Odour Control is Here

Molecular filtration is the most proactive, science-backed approach for controlling contamination and odour. It offers the best long-term solution to address the root of the problem and eliminate it at its source, rather than relying on ineffective solutions such as masking agents. Consider a molecular filtration upgrade for a healthier, more pleasant environment for your staff, facility, and community.

Frequently Asked Questions (FAQs) About Molecular Filtration

Q: Is molecular filtration the same as a HEPA filter?

A: The best HEPA filters, such as Camfil’s Absolute VG are certified to a minimum efficiency of 99.99% @ 0.3 microns; however that is for particulates, not harmful gases which are much smaller. Gas molecules can only be captured using molecular filters such as those that use activated-carbon media.

Q: How long does a molecular filter last?

A: High-quality molecular filters are engineered for longevity; exact filter life depends on the application. Some uses will be more demanding, such as heavy industrial chemical production, which will require more changeouts than a less demanding application like a gym. Filter life depends on contaminant concentration. By speaking to a molecular air filtration specialist, you can get accurate estimates based on experience with various applications and facility sizes.

Q: Is molecular filtration expensive?

A: The initial purchase price of a high-quality molecular filter may be high depending on the model, but TCO must be factored in. Maintenance costs, costs to do changeouts, and energy costs must all be considered and evaluated. A high-quality molecular filter is an investment in safety, compliance, and a better working environment. It can also help reduce exposure to liability.

Contact Camfil Canada

Camfil has air filtration experts who can help you improve your indoor air quality (IAQ) with expertise in addressing regional challenges and operational needs. Whether you seek to control hazardous emissions or improve the IAQ in your workplace, Camfil can help. To find a local rep, use this contact form, and someone will reach out to you. Contact form

About Camfil Canada Clean Air Solutions

For more than 60 years, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that enhance worker and equipment productivity, reduce energy consumption, and benefit both human health and the environment.

Media Contact:

Phillip Ilijevski

Camfil Canada Inc.

Sources:

With information from Camfil Canada Molecular Specialist Geordon Hoag

Connecticut Department of Public Health

Health Canada