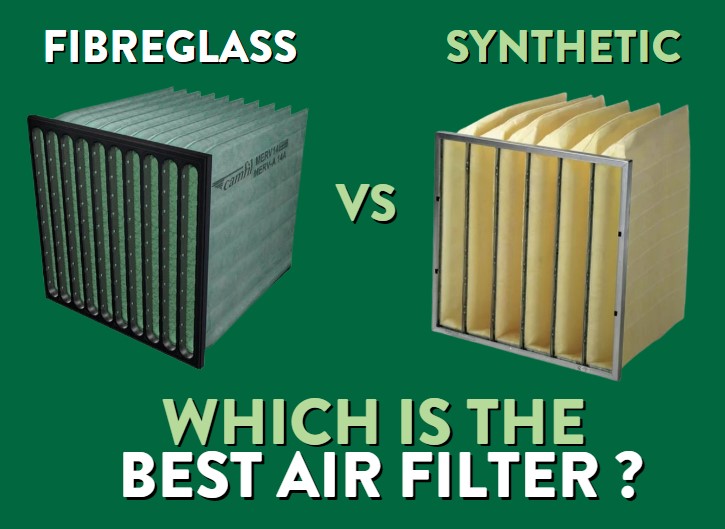

In air filtration, the debate between synthetic air filters and fibreglass filters has been ongoing, with synthetic filters still facing some challenges in competing with fibreglass filters. Originally, filters with fibreglass-based media dominated the market, particularly in the production of HEPA and bag filters. However, the high cost and intensive manufacturing process of fibreglass led to an increased market share for synthetic filters, which are easier and cheaper to produce. This article will compare synthetic and fibreglass filters, exploring their mechanisms, efficiency, and longevity and provide a comprehensive understanding of how these filters work.

Originally, air filters were made with fibreglass media. fibreglass was introduced in the manufacturing of HEPA filters and fibreglass bag filters. Then, synthetic filters began to emerge on the market, primarily due to the ease of producing them. fibreglass is expensive to produce and requires high heat to melt the raw materials used to make it, while synthetic filters can be made by simply melting plastics.

The first synthetic products were low-efficiency pads. However, they offered benefits such as being stronger and cheaper. Over time, the industry shifted towards using synthetics for higher-efficiency filters, leading to discussions of their pros and cons.

How do synthetic air filters work?

All filters operate based on five principles of filtration: straining, interception, diffusion, impaction, and electrostatic charge. The efficiency of an air filter depends on the percentage of each principle it employs. Initially, synthetic filters primarily used straining to collect large particles, which they did effectively due to their use of coarse fibres. These filters were also water-resistant, making them suitable for applications exposed to rain and other moisture.

As the market began to demand higher-efficiency filters, manufacturers had to incorporate electrostatic charge because the fibres were too large to achieve high efficiency solely through mechanical means. This enhancement allowed the filters to capture finer particles.

Do synthetic air filters remain as effective as mechanical filters after the electrostatic charge dissipates?

Fine fibres are required to achieve mechanical filtration with any air filter. The challenge with synthetic bag filters or high-efficiency filters has been producing fibres that are fine enough to produce the desired benefits. As a result, electrostatic charging was introduced.

Recent advancements involve the use of nanofibers, which allow for the production of finer synthetic strands. However, these also face challenges with dust-holding capacity, which can be less than that of fibreglass filters.

How does the electrostatic charge work?

Electrostatic enhancement is similar to the principle of the static charge a balloon produces when rubbed against human hair (electrons, negatively charged particles, are transferred from your hair to the balloon). To achieve electrostatic enhancement in filter media, the charge is generated during manufacturing as the fibres rub against each other. However, to achieve a higher efficiency, most filters pass through an electronic unit that applies electrostatic charge to the media.

The downside is that, like a balloon, these fibres can lose their charge over time, decreasing efficiency.

How long do synthetic air filters last?

The lifespan of an air filter depends on three factors: the time it remains in the system, the airflow passing through it, and the level of contamination. Each factor can significantly affect the filter’s longevity. The only way to accurately determine a filter’s lifespan is to check it regularly in a specific application. If outdoor and indoor contaminant levels remain relatively stable, this will help predict when the filter’s efficiency will begin to decline.

There isn’t a set timeline, like three, six, or nine months, for when filters will drop in MERV efficiency. A filter’s efficiency might decrease quickly or gradually; it could decline in just one day or may take an entire year. The only way to know for sure is through regular testing.

History of synthetic air filters

Initially, the only option was fibreglass filters, which included fibreglass pads, fibreglass HEPA filters, and fibreglass bag filters. This had been the case for a few decades. Then, synthetics started emerging on the market, primarily due to the ease of manufacturing.

Fibreglass is costly, requiring high heat to melt raw materials and create glass fibres. In contrast, the production of synthetic filters involves melting plastics, which is more straightforward and requires less heat.

The first synthetic filters introduced were low-efficiency pads. They were stronger and more affordable. Over time, engineers began to explore synthetics for higher-efficiency filter designs.

How do synthetic and fibreglass air filters work and what are the key differences with fibreglass filers?

As advancements were made and manufacturers aimed for higher efficiency, the fibres in synthetic filters were found to be too large for optimal performance. To address this, air filter manufacturers began adding an electrostatic charge to enhance filtration. While the other four principles of filtration were still applied to capture finer particles, the electrostatic enhancement proved crucial in improving effectiveness. The current challenge is to enhance synthetic filters without compromising their effectiveness, particularly regarding electrostatic issues.

The only way to achieve mechanical filtration in any type of filter is through the use of fine fibres. However, manufacturers couldn’t produce fibres fine enough in synthetic bag filters or high-efficiency filters to achieve pure mechanical filtration, so they had to incorporate an electrostatic charge.

However, advancements have been made with nanofibres, allowing for the production of finer synthetic strands. Still, there are other challenges to consider, such as dust holding capacity, which can often be less than that of fibreglass. While efficiency has improved, holding capacity can still pose a problem. At its inception Camfil was not opposed to synthetic media but understood the limitations of coarse fibre media.

Today, we benefit from lessons learned in the past in all areas of our personal and professional lives—and air filtration technology is no exception. At first glance, modern filters may look much like they always have, but engineers have continually refined their performance in ways that may not be immediately visible.

The term “filtration media” refers to the fabric component of an air filter. As filter technology evolved, some media types were developed using glass fibres, while others relied on synthetic materials. Media made from micro-fine glass fibres excel in maintaining high particle capture efficiency, due to the fine fibre structure associated with micro-glass. Historically, synthetic media were made from coarser fibre structures that rely predominantly on an electrostatic charge to achieve similar efficiency as fine fibreglass temporarily. As technology has developed, it is now more possible to produce filtration media with fine fibre synthetics. However, they do come with significant costs and other performance-related challenges, such as longevity.

In some ways, the development of these technologies resembled an Edison–Tesla-type competition, with advocates for synthetic media even attempting to portray glass fibres as potentially hazardous. This was a stretch, considering that nearly all HEPA filters used in sensitive settings, such as operating rooms, are made from micro-fine glass fibres.

Filtration technology has improved to the point where micro-fine fibres can now be produced with synthetic materials. Incorporating these fibres into a media can yield a filter with the highly maintained particle capture efficiency of a fine glass media but with the strength and moisture resistance of a synthetic media.

Are synthetic air filters more efficient than fibreglass air filters?

Initially, there was a strong emphasis on promoting efficiency in filters, especially since some were electrostatically enhanced. In early tests, these filters performed exceptionally well—better than comparable fibreglass products. Companies would advertise, “Look, this filter is a MERV 15 instead of a MERV 14,” highlighting its superior performance without realizing that over time, it would lose its charge and, thus, its efficiency would decline.

Due to these factors, synthetic filters began to flood the market. The fibreglass industry was slow to respond, and there was only one company that consistently championed efficiency and longevity: Camfil. Camfil rarely promoted synthetic products unless a customer specifically requested them. Camfil focused on fibreglass due to the concept of fine fibre filtration.

Why did Camfil mostly stick to fibreglass air filters?

Many suppliers, customers, and salespeople misinterpreted Camfil’s approach. Camfil was not opposed to using synthetic media; instead, it was always in favour of fine fibre because of its superior performance. Years ago, synthetic material producers could not manufacture fine fibres, which is why Camfil avoided them. Camfil aimed to provide the best air quality, advocating for fine fibres but also anticipating that advancements in technology would eventually lead to the development of synthetic fine fibres. We are beginning to see that now with nanofibres.

Camfil is gradually incorporating more synthetic products, but these new materials are designed to meet the fine fibre standards that Camfil has always upheld. Over time, these synthetic products will improve. However, there are still some challenges regarding the dust-holding capacity of certain synthetic media, which may be resolved in the future. It’s essential to clarify that when people say Camfil is shifting to synthetics, it is not actually the case. It is simply that the quality of synthetics has improved to include the fine fibres required for high-efficiency filters.

Promoters of synthetic filters often highlight three attributes of synthetic air filters: long life, high efficiency, and durability. While synthetics do boast durability and have shown high initial efficiency, past promotions focused only on current efficiency without discussing future MERV ratings.

The longevity of these filters was attributed to the fact that once they lost their charge, their efficiency would drop. Consequently, they weren’t collecting as much dust, which allowed the filters to last longer. This led to the misconception that they offered all three benefits simultaneously, resulting in the mischaracterization of synthetic media as “state-of-the-art.”

Do nanofibres help counter these problems?

Yes, nanofibres improve the efficiency of air filters. The strength has always been apparent, but nanofibres enhance their efficiency and help maintain it over time. However, the industry is still working on extending the longevity of these products to match that of fibreglass filters.

What’s the best approach to ensure efficiency and airflow are maintained correctly?

The first step is to verify that the filter you are using has an appropriate MERV rating. For instance, if you have a MERV 14 filter, it should consistently maintain that efficiency, fibreglass or synthetic. If you are confident in the efficiency rating through proper testing channels, you should have nothing to worry about in terms of filter strength and longevity as long as you use pressure gauges in your system.

For energy-saving measures, replace the filters at twice the initial pressure drop. Otherwise, if you’re maintaining a constant velocity, you can let the system run until the maximum pressure drop occurs.

One advantage of synthetic filters is that they typically start with a lower pressure drop. However, the average pressure drop for most synthetic filters is still higher than that of fibreglass filters.

Can synthetic media in air filters capture smaller particles and pollutants? What sizes can they trap?

Any nanotechnology-based filter will perform with the same efficiency as other filters, capturing particles from 0.3 microns up to 10 microns. In fact, the efficiency of a MERV 14 nanofibre-based filter is comparable to that of a MERV 14 fibreglass filter.

What is the maximum rating for a nanofibre synthetic bag or box filter?

A synthetic filter with nanofiber technology can reach a MERV rating of up to MERV 16.

While synthetic media is available for HEPA filters, testing these filters can be challenging because certain testing oils can clog the media immediately, rendering the filter unusable. It’s essential to be cautious about the applications used for synthetic HEPA filters. When testing, the oil may load the filter and cause irreversible clogging, necessitating disposal.

When comparing the filtration efficiency of synthetic media to traditional options, it’s evident that synthetic filters can compete effectively. However, they require closer monitoring than traditional media.

Can synthetic air filters protect human health?

Both fibreglass and synthetic filters can enhance building occupant health and productivity by reducing the number of airborne particles. This reduction helps address health issues and can alleviate symptoms associated with sick-building syndrome. To provide maximum protection and maintained MERV efficiency it is best to consult with an air filter expert to determine which product would work best.

Is it true that all synthetic media must have an electrostatic charge?

Coarse fibre filters typically require electrostatic enhancement. However, with fine fibres, such as nanofibres, there is no need for additional electrostatic enhancement.

All filters have some level of electrostatic charge. Even fibreglass has a slight electrostatic charge. Nanofibres, in particular, possess a natural electrostatic charge.

What about fibre densities?

The density within the structure can trap smaller particles that might otherwise pass through. With nanofibres, the density throughout the media remains consistent, but the actual thickness of nanofiber media is comparable to that of regular high-loft fibreglass—not wet-laid fibreglass. The amount of media per gram is nearly the same as fibreglass.

Can synthetic filters be more advantageous than HEPA filters?

Synthetic filters will not outmatch HEPA filters in terms of particle capture efficiency. There are two types of efficiencies to consider: ASHRAE efficiency, which ranges from MERV 1 to 16, and HEPA efficiency, which starts at 99.97% at 0.3 micron and above.

Are there advantages to using synthetic filters?

Yes, there are situations in which synthetic media, mainly when electrostatically enhanced, can perform well. If you install a synthetic filter rated at MERV 16 that hasn’t been tested at MERV-A, its effectiveness could decline over time, dropping to a lower MERV rating. If you replace the synthetic filter proactively before it loses efficiency, you can maintain MERV 16 efficiency in your building.

The challenge is that it’s difficult to know exactly when a filter starts to decline. Using a particle counter in your room to measure particle concentration could help indicate when to change the filter.

If you frequently replace a coarse fibre synthetic filter, you could maintain a higher efficiency rating. Still, it will also cost significantly more money, as you may need to change that filter five to six times more often than with a fibreglass or nanofiber filter.

Both electrostatic and fibreglass filters have their unique attributes, making them suitable for different applications. Fibreglass filters, with their high particle capture efficiency and durability, are ideal for environments requiring stringent air quality control, such as medical facilities, schools, and long-term care homes. Synthetic filters, enhanced with electrostatic charges, are cost-effective and versatile, particularly in settings where moisture resistance is prioritized. As technology continues to advance, the development of finer synthetic fibres may bridge the gap between these two types of filters, potentially offering cost benefits. The choice between electrostatic and fibreglass filters should be made based on specific conditions and desired outcome. This will ensure optimal air quality.

To find out more about how to choose the right air filter, or get a complimentary IAQ and air filtration site survey, please use this contact form.

About Camfil Canada Clean Air Solutions

For more than 60 years, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. Read more about Camfil Canada

##

With information by air filtration expert Berni Baier

Media Contact:

Phillip Ilijevski

Camfil Canada Inc.

T: 437-929-1161