By Phillip Ilijevski and Joe Brennan

MERV Air filter testing may not be top of mind for most people, but air filtration plays a major impact in building livability, comfort, and quality of life for occupants and visitors. Most people are likely not aware of the impact that the wrong filter can have on indoor air quality.

The information in this article is key for any industry concerned about how air filter technology affects the indoor air quality of its buildings or offices. An important factor in determining which filter to use for building managers is test results. In this article, we will take a close look at MERV air filter quality and testing and how testing in a transparent manner is crucial to evaluating and determining the efficiency of air filters.

The Evolution of MERV Air Filter Testing

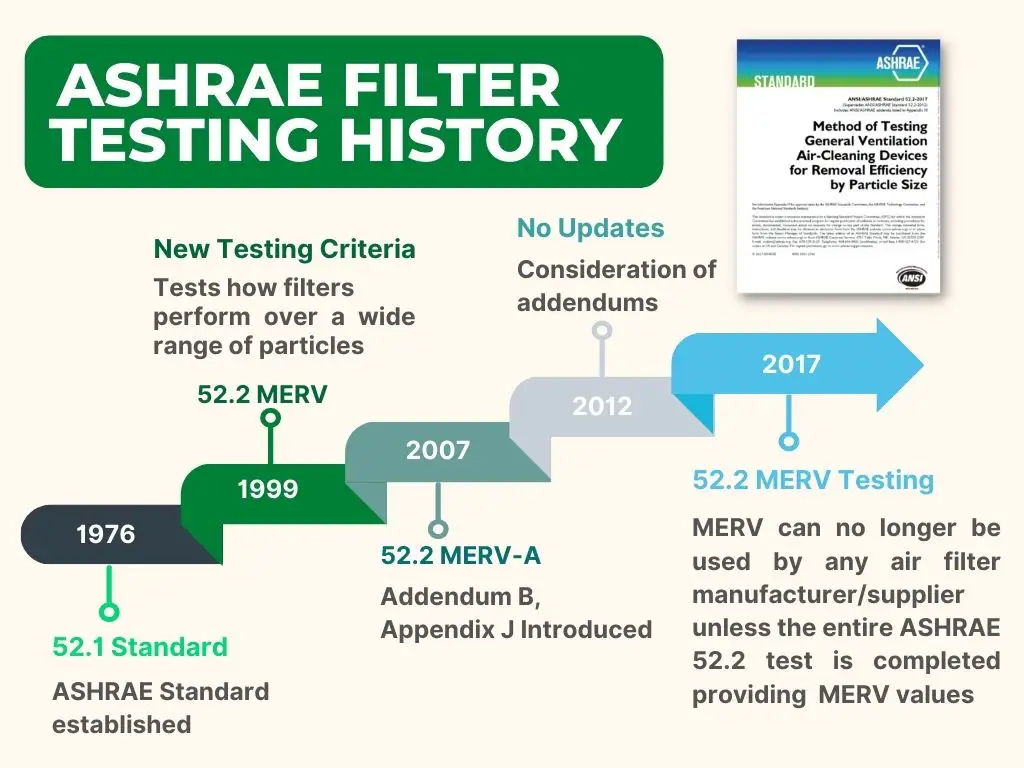

Laboratory testing of air filters has been available since the 1950s. In 1968, the American Society of Refrigeration, Heating and Air-Conditioning Engineers (ASHRAE) accepted the publishing responsibility for testing. The testing has advanced over the years, adapting each new version to evolving testing technology and capability. In 1999, ASHRAE introduced Standard 52.2.

ASHRAE Standard 52.2, “Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size,” using laboratory-defined parameters, evaluates the performance of one filter against another.

The ASHRAE Standard 52.2 Testing Method

What is MERV?

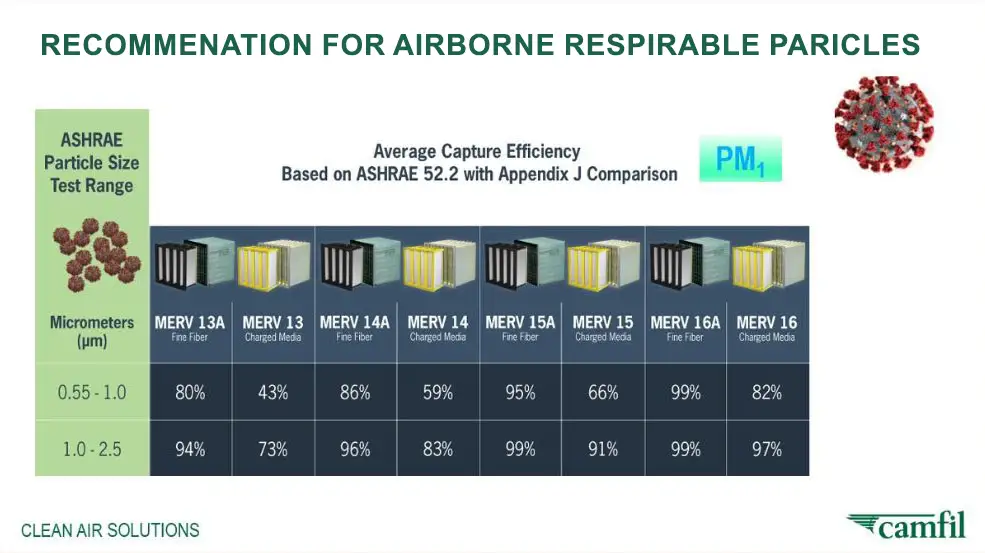

MERV, or Minimum Efficiency Reporting Value was introduced to improve the understanding of how filters perform over a wide range of particles and to allow users a way to compare the effectiveness of one filter versus another. The higher the MERV rating—on a scale from MERV-1 to MERV-16*— the more efficient the air filter. What is a MERV rating?

The ASHRAE Standard establishes a test procedure for evaluating air filtration devices. It utilizes a standardized loading dust to simulate loading “during service life.” A MERV Value is established based on how the device performed over three particle ranges.

*Although a MERV rating of 17 to 20 is advertised from time to time on some air filters, these are not valid MERV ratings. MERV 17-20 were an original concept during the design of the earlier standards but were later removed. For filters in this range, HEPA testing standards are utilized.

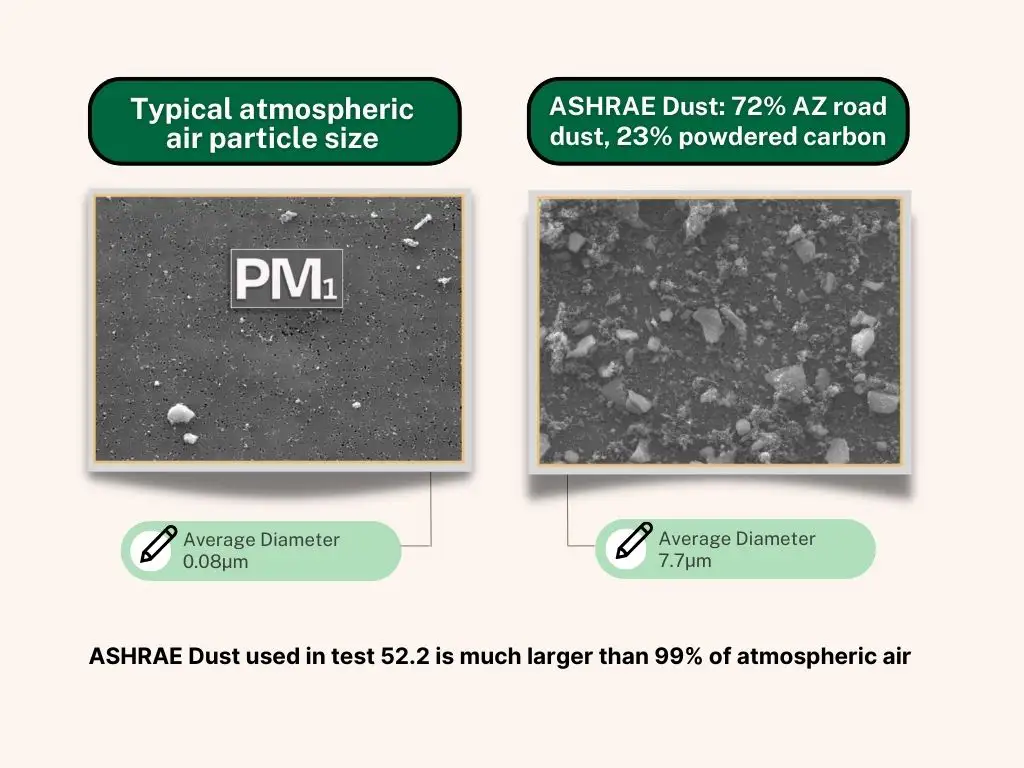

The Problem with ASHRAE Test Dust

ASHRAE test dust is 7.7 microns in size on average. Using a combination of Arizona road dust, cotton linters, and carbon particles, this test dust attempts to simulate “real world conditions.” However, the ASHRAE test dust does not actually represent how filters are typically challenged in real life (most particles being 1 micron and smaller).

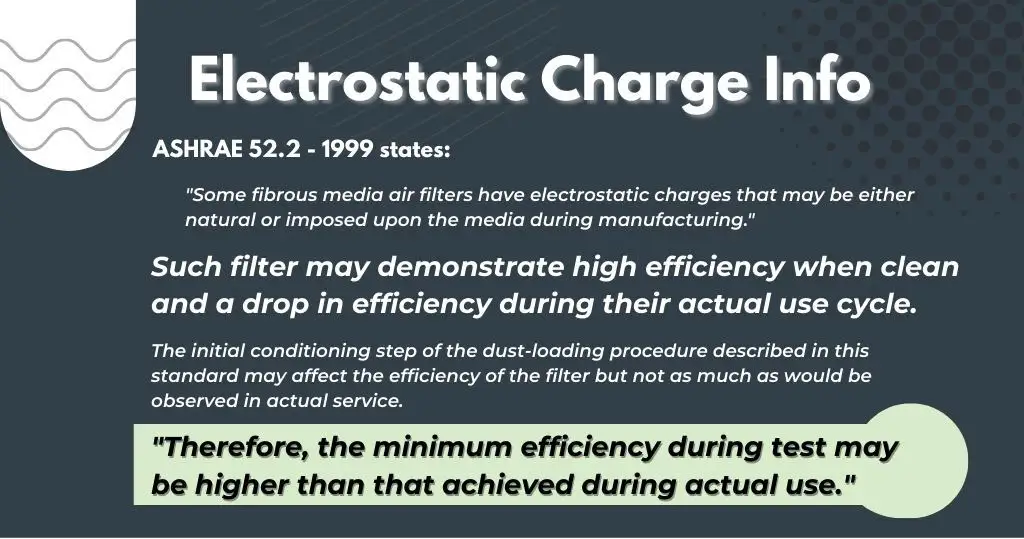

Degradation of particle efficiency has been known and acknowledged by ASHRAE since the inception of the 52.2 standard in 1999. In fact, ASHRAE stated very clearly that some air filters have electrostatic charges that are either naturally imposed, or imposed during the manufacturing process. This type of air filter will demonstrate a very high level of particulate efficiency when clean, but will drop in particulate efficiency during its actual use cycle.

The Conditioning Step

The conditioning step within the 52.2 test procedure, loads 30g of ASHRAE dust which only conditions the air filter for dust loading and unlike atmospheric air, this conditioning step does nothing to eliminate any electrostatic charge. Originally, it was thought this procedure could help remove some charge, resulting in high efficiency, but the committee quickly determined that was not possible with an ASHRAE dust loading step.

What is the ASHRAE Standard?

Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size

- Establishes a test procedure for evaluating

- Performance of general ventilation air-cleaning devices as a function of specific particle diameters

Loads with standard loading dust to simulate loading “during service life”

Loads with standard loading dust to simulate loading “during service life”- Defines standard aerosol and generation procedure

- Defines method of measuring efficiency

- Establishes performance specifications for the equipment used

- Defines method of calculating results

- Establishes Minimum Efficiency Reporting Value (MERV)

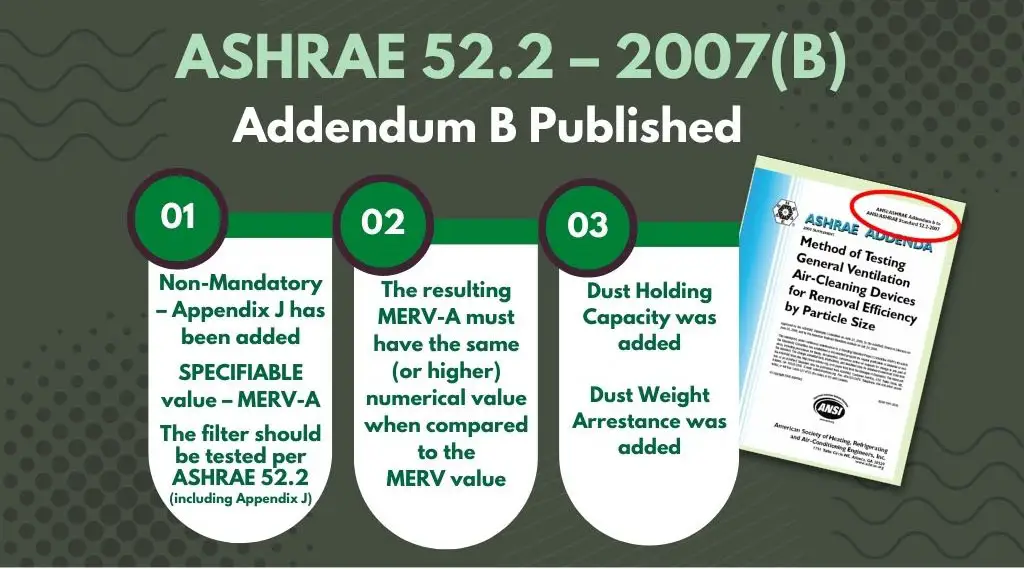

ASHRAE Standard Appendix J

Since its inception, the ASHRAE 52.2 Standard Committee has been debating the issue of air filters that drop in efficiency after installation. Consensus on whether to include this parameter in ratings could not be reached due to conflicting interests.

As a compromise, an optional test method was adopted and placed in the Appendices so there would be a clear procedure, defined by industry experts, for users who wanted confirmation assurance that the proposed air filters would perform as expected throughout their entire life.

Appendix J is titled “Optional Method of Conditioning a Filter Using Fine KCl Particles to Demonstrate Efficiency Loss That Might be Realized in Field Applications.” -The results can expose air filters that are not capable of performing at their published MERV rating throughout their life. Appendix J can be found on page 50 of this PDF document.

While ASHRAE Standard 52.2 is a great test protocol that dramatically moved the industry forward, some fixes are still needed.

The conditioning step in Appendix J section of ASHRAE 52.2 eliminates the most glaring problem – the reporting of a MERV value which is NOT the Minimum Efficiency Reporting Value for many of the filters tested.

“Appendix J was the result of an ASHRAE-funded research project RP-1190 — ASHRAE FILTER TEST STANDARDS 52.1 AND 52.2. Research Triangle Institute completed the research and developed the new test method. However, implementing this into the standard was a daunting task as the media manufacturers who made the electrostatically-charged media and air filter manufacturers who used this media want no part of this in the standard. They have been taking advantage of the 52.2 designation that reports MERV values much higher than their filters or media actually perform.”

– Don Thornburg, Camfil Filtration Research Services Manager

All members of the ASHRAE 52.2 Committee approved the designation of MERV-A for air filters tested per Appendix J of 52.2. At the time of acceptance of Appendix J, these were some of the companies with representatives on the committee which approved the addition: AAF, Camfil, Filtrair, Filtration Group, Kimberly-Clark, Viledon, 3M.

Reading an ASHRAE Test Report

ASHRAE testing standards are under continuous maintenance by the Standing Standard Project Committee (SSPC) following established procedures, and it strives for consensus within the members of the committee.

There are many reputable laboratories in North America providing information in a transparent manner that allows end-users to evaluate products so that they can determine the best performance. There are also some facilities that may not perform the testing to the strictest of standards which can give inaccurate information.

An ASHRAE test report must include a complete description of the air filter being tested including the manufacturer’s part number.

All reporting data required by the Standard should be listed including:

- Airflow

- Initial resistance

- The MERV at airflow

- E1, E2 and E3 values from which the MERV is derived- (E1= 0.3-1.0µm E2= 1.0-3.0µm E3= 3.0-10.0µm)

- Final resistance matching test definition

- Dust holding capacity (DHC)

- Arrestance in percent

The test data should be five years old or less.

Professional labs include a file designator or test number to allow users to confirm the data.

The Appendix J portion of the Standard requires that the entire test be repeated on a second air filter, as it is impossible to run both tests on the same filter as each test is destructive.

The second air filter is then tested using all of the previous testing requirements as listed for ASHRAE Standard 52.2.

The value that is determined by this additional testing is presented as MERV-A.

The latest version of the Standard referenced here is available for order through the ASHRAE Bookstore www.ashrae.org.

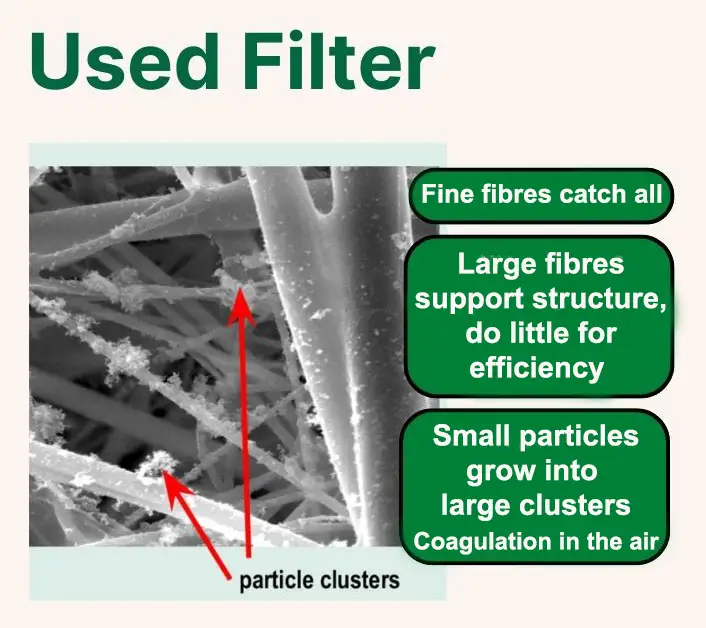

In the case of an air filter, the reduction in charge over a short period translates to a degradation in the fibers’ original ability to draw particulates to the media fiber. Conversely, there is a mechanical means of filtration that effectively locks out particles based on the density of the fibers woven together. The finer the media fibers, the tighter the lock becomes on the particles.

The report should include Appendix J of ASHRAE 52.2

The efficiency of the filter when it is installed has to be the same throughout the life of the air filter. This is especially important with higher efficiency filters designed to protect the health of building occupants; filters that drop in efficiency typically suffer the most and don’t perform as well in filtering smaller lung-damaging particle size ranges. The MERV listed on the test report should match the MERV-A of Appendix J of that report.

More information on PM1 and health

MERV air filter tests should be certified by an engineer, with additional details listed including the test duct operator as well as the manufacturer and model of the particle counter(s)

It must be apparent that two individual air filters were used for the individual portions of the test

If there is only data for one filter, or if the data matches in both sections, it is unlikely that the entire test was performed correctly and corners were likely cut during testing. Data from one filter to another will vary due to construction variances.

All the steps must be performed including testing duct preparation

The Standard requires confirmation of:

- Background concentration testing

- Aerosol concentration measurements

- Particle size ratios

Additional items that should be reported include:

- Cumulative conditioning duration

- Cumulative conditioning counts and conditioning with potassium chloride (KCI)

Dust holding capacity for both the Standard test and the MERV-A conditioned air filter test should also be reported.

The report must clearly distinguish data between the two tests

Appendix J values should be clearly identified. If not, it is possible that results were extrapolated and the testing data would therefore be unreliable. The lack of clarity makes it difficult to assess the validity of the data.

Can the testing lab confirm the values on the test report?

The information on who to contact should be noted clearly on the report. The lab should also be willing to send a hard copy of the report to the user for verification without charge.

The test must be certified by a resident mechanical engineer

A mechanical engineer requires an understanding of core concepts involving air filtration, including mechanics, kinematics, thermodynamics, materials science, structural analysis, and electricity.

Quality Air Filter Tests

Camfil test reports provide all of the data for the base of Standard 52.2 and Appendix J; no shortcuts, no missing data. Customers want air filters that perform at their rated efficiency. They expect a MERV-14 to be a MERV-14 at three months or even two years down the road. Appendix J testing is indicative of continued, maintained MERV efficiency throughout the life of the air filter.

Maintained Air Filter Efficiency and Transparent Tests

Although all test result factors should be considered important, maintained efficiency should be a strong concern for all involved. Camfil publishes all related data on the front page of every test report along with four additional pages of supporting data detailing all of the parameters used in the testing. This is consistent with ASHRAE reporting requirements for MERV air filter testing.

Camfil also includes all of the required base information to allow in-depth air filter performance evaluation. The main ASHRAE Testing Facility is located at Camfil’s North American Headquarters in Riverdale, New Jersey. The facility also includes four additional testing ducts that are designed to evaluate air, using real conditions over time.

Camfil also includes all of the required base information to allow in-depth air filter performance evaluation. The main ASHRAE Testing Facility is located at Camfil’s North American Headquarters in Riverdale, New Jersey. The facility also includes four additional testing ducts that are designed to evaluate air, using real conditions over time.

Simulated testing ducts allow Camfil to provide highly accurate data as to how an air filter will perform under ambient conditions.

Always look for filters that maintain their efficiency, have the lowest average pressure drop, and provide the longest filter life. By doing so, you can be assured the product that you purchase will reduce landfill waste instead of using air filters that have to be changed more often. Changing filters less often also means reduced labour costs. You can also rest assured that good indoor air quality can be confirmed.

Camfil welcomes visitors on a regular basis. Most of those visitors find our testing laboratories to be the highlight of their visit. Many send filters from competitors to test them against Camfil air filters to observe the performance differences. Camfil Testing Facilities

Camfil Solutions

Camfil produces filters such as the Hi-Flo ES and the Durafil that not only filter harmful contaminants but also help to save energy. These fine fibre filters retain efficiency and have a lower average pressure drop for better airflow. The key to cleaner indoor air is better air circulation.

Contact Camfil Canada to get expert advice on how to improve the air quality in your office or your building. Click here for our contact locator

About Camfil Canada Clean Air Solutions

For more than half a century, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. Read more about Camfil Canada

##

Media Contact:

Phillip Ilijevski

Camfil Canada Inc.

T: 437-929-1161

F: Follow Camfil Canada on Facebook

L: Follow Camfil Canada on LinkedIn

T: Follow Camfil Canada on Twitter

Sources: The sources will be updated