There are many questions to be asked when it comes to air filtration systems and air filters and their impact on energy consumption. Today, as energy is becoming more expensive, and climate change has become the dominant issue facing us, energy savings is becoming more and more important as we move further into the 21st Century. This article will focus on how you can save energy by improving your air filtration system and how to save energy by choosing the right air filter.

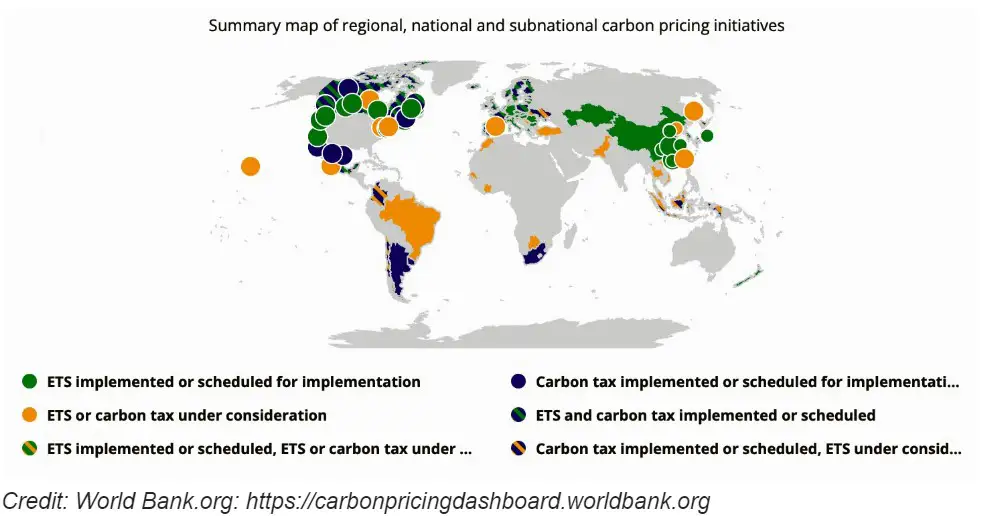

Governments are creating more incentives for energy savings in Canada and many other parts of the world. There are also a growing number of countries that have implemented emissions trading systems (ETS) and carbon taxes, Carbon Pricing World Bank. The Canadian government and provincial governments have incentives for electric and hybrid automobile purchases, Zero Emission Vehicle Incentive, but did you know there are also tax credits and incentives for energy savings that can be taken advantage of such as Canadian Tax Incentives for Business and Better Buildings Energy Saving Incentives for Business? See also: Incentives for green retrofit and sustainability

There are many advantages to rethinking your current air filtration setup:

- Lowering your energy bills

- Receiving incentives

- Offsetting carbon emissions

- Future-proofing your air filtration system

- Improving the environment, etc.

How Can You Save Energy with HVAC Air Filters?

One of the best ways you can reduce overall energy consumption in your building is to choose the right air filtration system. That means designing an air filtration system, including the air handling unit, that is built for efficiency and energy savings. It also means installing premium HVAC filters that will allow maximum airflow and maximum filtration of harmful particles to protect HVAC equipment in addition to building inhabitants.

Can I Save Enough Energy with Every Type of Fan in My Air Filtration System?

No, you cannot save a discernible amount of energy with every type of fan in your air filtration system. The best way to reduce electricity consumption is to install a Variable Frequency Drive (VFD) in your building. A variable frequency drive (VFD) and the right type of air filter can minimize the energy used by the fan motor and save you money.

Variable Frequency Drive Versus Constant Speed Fan- Which Air Filtration System is Better for Energy Savings?

What is a Variable Frequency Drive (VFD) control for fans?

A VFD controller adjusts the speed of the fan to the amount of pressure that is on the air filter. The higher the pressure, the more the fan speeds up, which in turn uses more energy. But naturally, when you install a brand new filter in your air filtration system, the fan will start at a lower speed.

It’s not just the filters that bring energy savings. The VFD allows operators to change the airflow depending on the time of day. For example, in a school when all students are in class, you can ramp up the fan. But at night when the building is empty, you can reduce the speed of the fans on a timer, for instance from 10pm to 7am, reducing energy usage. This flexibility is great for saving a great amount of money and can help you save energy with efficient air filters.

Why Do Some Property Managers Run VFD-controlled Fans at 100%?

They run VFD-controlled fans at 100% because the air filtration system or the air filters they choose are not designed for the load requirement of the rooms. The more occupants in the building, the more airflow is required for adequate indoor air quality and comfort levels.

Some purchase a VFD in order to get credits or incentives from governments to save on the expense of installing a new air filtration system. They receive gold stars or accreditation from organizations such Building Owners and Managers Association (BOMA) or Leadership in Energy and Environmental Design (LEED) for efficiency and energy savings, but then proceed to run the fans at 100%. This obviously defeats the purpose of green building certification.

What is a Constant Speed Fan?

With a constant speed fan, when you install an air filter, the fan will keep turning at the same speed whether the filter is clean or dirty. What then happens is, as the filter loads and gets dirty, the airflow into that area starts decreasing.

Constant Speed Fans and Energy Savings Explained

If you install an air filter with a lower average pressure drop in a system with constant speed fans, more air is delivered into the room which the fan must now overcome. However, that also means the thermostat doesn’t cycle as often. So now you are saving on that energy aspect, although that setup is not as predictable or as reliable for energy savings as a VFD.

While you may state that you are using less energy, you cannot get any rebates or credits if you use a constant speed fan.

Do Fan Walls Help Save Energy in Air Filtration?

As mentioned previously, VFD HVAC units normally have one fan drawing in the air, and speed is adjusted on that fan. Some of the newer units will actually have a wall of multiple smaller fans. It somewhat works like a VFD, but instead of changing the speed of the fan, an operator can shut off some of the fans. So when you don’t need as much air, you can for example, run half of the fans and can save energy.

The type of fan system is important, but so is the filter. Using a more energy-efficient filter is much more economical in terms of energy savings than changing an air filtration system or an air handler.

Space Availability and Alternatives in Air Filtration

Do I have the space to install better filters with higher efficiency and lower pressure drop?

Many HVAC units are designed for the present estimated requirements of the building, using minimal space. For example, if they only need a six-inch filter in the air handling unit, they will design the air handling unit for just six inches of filter space. In these situations, it may be difficult to promote the optimum energy saving air filter due to space limitations.

The Best Approach is to Have Latitude

Designing a building to have an adaptable air filtration system is the best approach so in the future you don’t have to worry about having to make big changes which can be quite expensive.

If you are at the point that you want to save more energy or you want to improve the indoor air quality, the following three questions should be asked in a feasibility study:

- Do you have the space from the filter to the coil, or is anything behind that air filter?

- Does the present design allow you to simply install a better air filter with lower average pressure drop after making small adjustments?

- Can you retrofit the system to install different types of frames that will allow you to place better filters upstream?

If the answer to any one of those questions is yes, then it’s up to an energy savings consultant to try and work with the client to have better air filters installed. If the answer is “no” to all three, it will be difficult to use energy saving filters without considerable hardware/labour investment, but it is rarely the case that at least one of the three options are not possible.

Choosing the Correct Filter and Installation Design for a More Energy Efficient HVAC System

Building Engineers will choose whichever filters they feel are needed for a specific building or a specific area of a building. ASHRAE specifies what it believes is needed for a building or area. Most often, it ends up being a MERV 8 air filter.

Due to the COVID-19 pandemic, there is currently increased scrutiny and demand for filters that better protect human health. There is also more pressure to be more sustainable and to use air filters that save energy. For more effective airborne particle removal of respiratory threats such as those posed by COVID-19, MERV 13 is viewed as the target efficiency. This is considered the minimum efficiency to capture particles that affect people, while lower efficiency filters are normally for protecting equipment or protecting secondary filters.

Most building owners, property managers, and facility managers are content with MERV 13 filters. But what if they want higher efficiency filters? In this case, you have to look at whether the fan can handle the pressure drop along with the available space.

Can the Fans Handle the Resistance from the Higher Efficiency Air Filter?

Fans are able to handle only so much resistance. After a certain point they either stop moving air or they burn out.

If you want to increase the efficiency of your system, the first thing you need to do is make sure that the fan you are using is able to handle the filter you install, because in most situations, higher efficiency filters have a higher pressure drop. If the fan is unable to handle the resistance, the 2 options are, increase the size of the fan or increase the number of filters within the filter bank.

What is the Ideal Air Filter for the Air Flow that I Require?

Most air handling systems are designed to run at 300-500 fpm. However, over-sized systems are now favoured to decrease the VFD speed and save energy. The designed air flow should dictate the type of filter utilized. For example, the most energy-efficient filter is the Camfil Durafil® ES, which in standard applications, could last 3-5 years, depending on the prefilters used and dirt load. Should a system be designed to run on average at 200-300 fpm, a Durafil ES might not be recommended as it would last longer than the maximum rated life of this filter. In order to help choose the correct filter, Camfil suggests inquiring about a Life Cycle Cost (LCC) analysis.

What Are the Benefits of Pleated Air Filters?

The optimum energy-saving system is a single-stage filter design. Should this not be possible, pleated filters, or even low efficiency bag filters should be used as opposed to flat pad filters. The main benefits of these filters is they have a longer life and lower average pressure drop than pads.

Another consideration if you are seeking to increase air flow and decrease energy usage, is to actually install the prefilters into a V-shape. In doing so, you can now install twice as many filters in the same space which will decrease the pressure drop by 50% and, if using a VFD, save energy.

Why is a Coarse Fibre MERV 13 Air Filter a Bad Idea?

Because some users have limited space for air filter installation in their air handling unit, they can only fit in pleated MERV 13 air filters. The main problem with a coarse fibre MERV 13 filter is it will not maintain its efficiency and will decrease in efficiency after installation. Users will find that even though they pay extra for MERV 13 filters, they may be getting the same performance as a MERV 8 filter after as little as a few weeks of usage.

Read more about MERV filter testing and requirements here.

Single Stage Air Filtration Versus Multi Stage Air Filtration

Will we always need multi stage filters, or are there alternatives? -A discussion of the benefits of multi stage vs. single stage air filtration

Many smaller air handling units normally use single stage air filters. Larger air handling units, such as walk-in air handlers, usually use a two or three stage air filtration design.

What is a Two Stage Air Filtration System?

In a two stage air filtration system there is a prefilter and a main filter.

The prefilter’s purpose is to either:

- Protect HVAC coils by stopping large particles from building up on your heating/cooling coils (the build up of dust particles can reduce the efficiency of your coils)

- To protect the secondary filter (the purpose of the secondary filter is to protect human health in this case)

The secondary filter is normally a MERV 13 or higher. The prefilter is normally up to a MERV 8 or 9 and in rare instances, up to a MERV 11.

When you have two filters in a system, you are generally not improving or increasing efficiency.

All you are doing is adding resistance (pressure drop) and extending the life of the secondary filter.

There was a misconception in the past that the prefilter would remove a percentage of harmful particles and then subsequently the main filter would remove the remaining harmful particles, but that does not happen in reality…. An air handling system will be as efficient as its final filter. For example, if you have a MERV 13 filter, or a MERV 13-A filter, it doesn’t matter how many prefilters you have in front of it, in the majority of situations, you will have a MERV 13 or MERV 13-A efficient system. The overall Particle capture efficiency will be the same.

Can You Convert a Two-Stage Air Filtration System into a Single-Stage Air Filtration System and Still Save Energy with Air Filters?

It is not difficult to convert a two stage air filtration system into a single stage air filtration system. You simply have to replace the secondary filter with a Hi-Flo® ES. In most cases, no retrofitting is required.

Some of the considerations before making a change from multi-stage to single stage are:

- If you have a prefilter that is protecting coils and the secondary filter after the coils, you will have to place the Hi-Flo ES in the very front of the air handling unit to do all the work. If you have the space behind the present frames, you can use the same prefilter frames for the Hi-Flo ES bags. If you do not have the space behind but have the space in front of the frames, a retrofit frame, the Camfil Camextender, is available that attaches to the prefilter frame (in this type of installation the filter will simply protrude out in front of the frame)

- As a last resort, if a bag filter will not fit with minor adaptations, you will have to retrofit the AHU and move the frame further forward to make room for the bag filter. In the majority of situations, it is not an overly complicated or expensive retrofit process

There are many benefits in converting a 2-stage filtration system to a single stage system:

- Dramatically increase airflow

- No decrease in efficiency

- Decreased waste and labour

- Decreased energy consumption

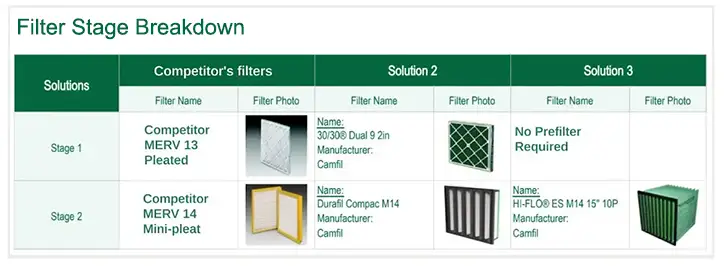

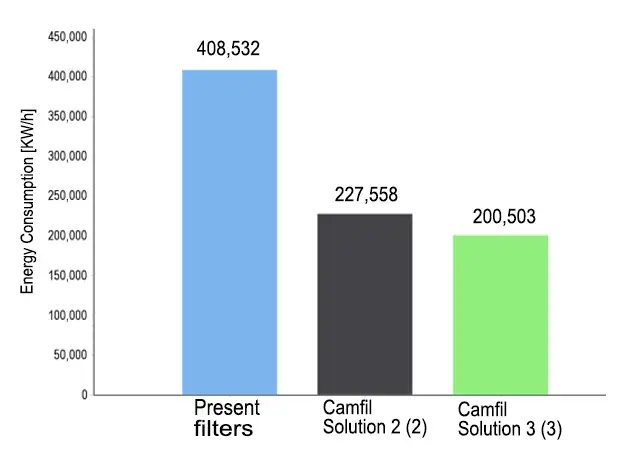

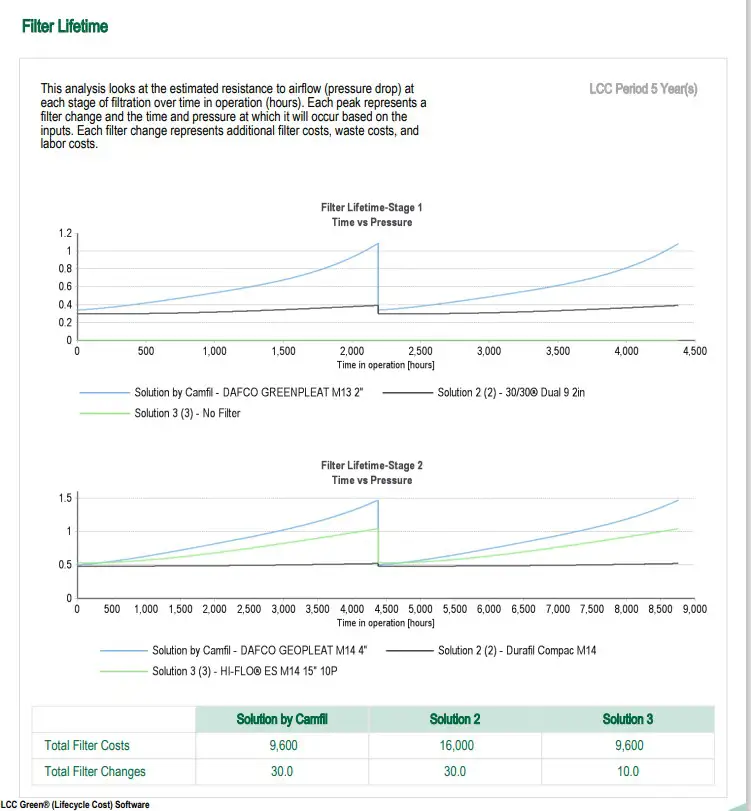

Here is a 5 year energy usage comparison (the lower the better) of a typical air filter design (present filter), Camfil Solution 2 (2) a two stage, premium filter design and Camfil Solution 3 (3) a single stage Hi-Flo ES filter. Although the Hi-Flo ES itself has a higher pressure drop after about 4,400 hours of operation, the overall combined pressure drop is lower due to no prefilter.

| Present Filters | Camfil Solution 2 | Camfil Solution 3 | |

| Total Energy Costs | $49,024 | $27,307 | $24,060 |

| Total CFM | 32,002 CFM | 32,002 CFM | 32,002 CFM |

| Average Resistance -Stage 1 | 0.60 | 0.33 | 0.00 |

| Average Resistance -Stage 2 | 0.89 | 0.50 | 0.73 |

| Fan Efficiency | 60% | 60% | 60% |

| Energy KW/h | 408,533 | 227,558 | 200,503 |

| TCO elements | Present Filters | Camfil Solution 2 | Camfil Solution 3 |

| Energy Cost | 49,024 CDN | 27,307 CDN | 24,060 CDN |

| Filter Cost | 9,600 CDN | 16,000 CDN | 9,600 CDN |

| Labour Cost | 100 CDN | 100 CDN | – CDN |

| Waste Cost | 95 CDN | 95 CDN | – CDN |

| CO2 Impact | 540,489 lb | 301,059 lb | 265,266 lb |

| Landfill Impact | 18.48 yd3 | 22.77 yd3 | 7.78 yd3 |

| LCC Time Period | 5 yrs | 5 yrs | 5 yrs |

| Total Cost of Ownership (TCO) | 58,819 CDN | 43,502 CDN | 33,660 CDN |

Does Moisture in an Air Filter Affect How Much Energy You Can Save with Air Filters?

Many people don’t realize air filters are designed to collect dry particulates, not moisture or humidity. When water collects on a filter, openings in the filter will be blocked and air flow will be constrained. The pressure drop will increase.

If a lot of moisture is entering the air handling unit on a regular basis, the pressure drop is going to increase and if you have a VFD, the VFD is going to ramp up and start using more energy and with a constant speed fan air flow will be reduced.

If the filter is too close to the dampers and louvers, then there is a chance you will be drawing in rain from outside. This happens because the fan is running too fast and sucking the air through the dampers that are designed to keep moisture out.

If this is the case, your options are to:

- Decrease the flow rate so the moisture is not drawn in

- Build a ‘doghouse’ to eliminate the moisture from getting near the louvers

- Move the filters further downstream

Today, many air handling units have humidifiers in them. Humidifiers in front of filters can possibly cause issues and they need to be examined and resolved individually. In most cases, an air filter expert can guide you in terms of your installation needs. If the installation is very difficult, you may need to have a mechanical engineer provide advice.

What Different Types of Air Filters are Available in Order to Help Save Energy?

Prefilters

There are two basic types of prefilters, fiberglass or synthetic media flat pads or rolls, and pleated filters. Flat pads have a higher pressure drop than a pleated filter. With pleated filters there is more media in the filter in the same opening and therefore they have a lower pressure drop than a pad. Media pads rated at MERV 8 are available and are INITIALLY less expensive but must be changed more often, increasing labour costs. They also have a higher average pressure drop, which increases energy consumption.

Pleated air filters

There are important factors to think about when selecting the right air filter:

- Are the filters electrostatically enhanced? These filters will lose efficiency over their life, so be sure to ask for an Appendix J test report to confirm this.

- Is the pleated filter designed properly to let the air flow through? Many pleated filters decrease the number of pleats to reduce initial costs or utilize backing that does not maintain pleat integrity and will not allow full media loading throughout the life of the filter. Either of these will decrease the life of the filter and increase energy consumption.

- Do you have room for a thicker filter or can you accommodate a “V-bank” configuration? A 4” thick pleated filter will last longer and have a lower average pressure drop than a 1” pleated filter at the same velocity. If you can put the filters in a V-bank configuration, you can double the number of filters in the same area which dramatically decreases energy consumption. Also, a general consensus exists that “ for every 25% decrease in pressure drop, filter life will be doubled.”

With a standard pleated filter, a one inch filter will last approximately two months, a two inch filter 3-4 months, and a four inch filter will last approximately six months. Switching to a premium type of pleated filter, could double the life of an air filter.

Box Filters and Bag Filters

Box Filters

Box filters and bag filters come in the same efficiencies. Box filters can start at MERV 9, which would normally be used as a prefilter, and can go to MERV 16…(MERV 17-20 does not exist as some people promote).

One way box filters are different from bag filters is that they are rigid and stronger. Sometimes, bag filters can tear, with box filters this is uncommon. Another advantage is certain box filters can withstand higher temperatures or higher humidity depending on the media that is used.

A con for certain box filters is that they are normally 6 to 12 inches deep. This makes them more difficult to carry when installing them in rooftop units for example, and this can be time consuming and cumbersome.

Another con is that there is more material involved, so box filters take up more space in disposal bins.

The greatest advantage in using a specific box filter is with a proper prefilter, such as the Camfil Durafil ES, it can last up to five years without needing replacement.

An important thing to consider when buying a high efficiency box filter is to make sure it is constructed with a fine fibre media that does not lose efficiency over its life. If it is a coarse fibre filter, make sure you get a test report that proves the media does not lose its efficiency after installation.

Bag Filters

As mentioned in the previous section, bag filters come in the same efficiencies as box filters. The only difference is that you can collapse them and fold them up so they don’t use as much waste in a disposal bin.

Contrary to popular belief, a bag filter does not need to contain more pockets or longer pockets in order to work properly or last longer. A more important consideration is for all the pockets to be fully inflated so that you are utilizing the entire media and collecting the particulate throughout the filter.

Anytime you have any of the pockets sagging and no air going through properly, you are going to shorten the life of that filter, increase resistance and increase energy consumption.

First off, make sure the bags are installed properly. Bag filters should be installed whenever possible with the seams running vertically so they stand up straight as opposed to horizontally where the bags lay flat on one another. It requires a certain amount of air pressure to inflate horizontal bags so they extend outwards.

If the bags are installed correctly, but you find the bags are still sagging in your air system, then install a filter with shorter pockets or with a reduced number of pockets so that pockets will be fully inflated.

The next question is, does the filter require prefiltration in order to help extend its life? As mentioned previously, Camfil’s Hi-Flo ES bag filter does not require a prefilter and is guaranteed to last as long as your present bag filters.

What is the Best MERV Air Filter?

The best air filter is the one that has a MERV-A rating, such as a MERV 13-A or MERV 14-A, which will maintain its efficiency over time.

Look for Lowest Average Pressure Drop, Not Lowest Initial Pressure Drop

Some companies claim to have the lowest pressure drop but this may be based on the INITIAL pressure drop as opposed to the AVERAGE pressure drop. The question you should be asking is “how quickly does the filter increase in pressure?”

A filter that starts low in resistance but increases quickly through its life will use much more energy than a filter that starts at the same pressure drop (or even higher) but GRADUALLY increases resistance through its life. These companies falsely state that because they have a lower INITIAL pressure drop, their filter will save more energy. In reality, as proven by robust testing, this is not the case. More on MERV air filter testing

Air filters guaranteed to maintain efficiency and have the lowest average pressure drop: Example 1: Box Filter- Durafil Example 2: Bag Filter- Hi-Flo ES

What Are the Benefits of Camfil Having an Environmentally-Friendly Approach in Terms of Materials Usage and Performance?

Camfil’s philosophy has always been to have the greenest filters available and it applies to all factors that we have discussed above, which is the pressure drop, the efficiency, the longevity of the filter and the waste factor.

For further information, please use this contact form and an air filtration expert from Camfil will answer any questions you may have.

See our new interactive Camfil City tool to find out how to improve indoor air quality while saving energy in a variety of environments such as schools, hospitals, factories, office buildings and more Camfil City

About Camfil Canada Clean Air Solutions

For more than half a century, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. Read more about Camfil Canada

#

Media Contact:

Phillip Ilijevski

Camfil Canada Inc.

T: 437-929-1161

E: Phillip.Ilijevski@camfil.com

L: Follow Camfil Canada on LinkedIn

Resources

Interview with Berni Baier, Camfil Air Filter Expert

https://www.camfil.com/en-ca/products

betterbuildingsbc.ca

resourcehub.bakermckenzie.com