Life Cycle Cost (LCC) is a sophisticated software tool that helps businesses optimize their systems and reduce operating expenses. It can help companies optimize their operations in air filtration. It considers factors such as air filter efficiency, lifespan, labour costs for changeouts, purchase costs, disposal fees, and energy consumption. In this article, we will examine the benefits of using LCC in your clean air solutions.

What does LCC forecast in air filtration?

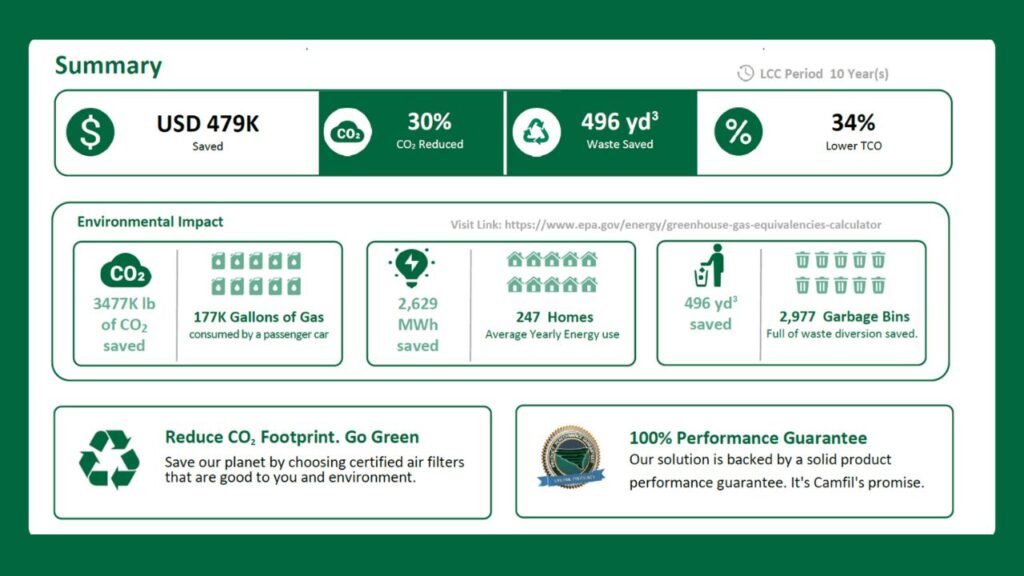

Using real-world data from facilities worldwide, LCC software can accurately predict long-term costs, enabling informed decisions about the best filter combinations. This maximizes profitability and minimizes environmental impact.

The total cost of ownership (TCO) of an asset encompasses all costs associated with that asset throughout its entire lifespan. This includes the initial purchase price, maintenance, energy consumption, and disposal costs. LCC assists businesses in making informed decisions about their investments.

A critical aspect of LCC is forecasting the filter life and predicting when replacements are needed.

LCC shows using budget air filters will cost more in the long term

If you use an inexpensive, low-quality filter or a low-efficiency filter, it can lead to problems. Although you may not see the particles in the air—because almost 99% of them are submicron in size—billions of particles can pass through these filters. As these particles accumulate, they can affect various components downstream, such as fans, belts, pulleys, and circuit boards, especially in something like a server room.

If these particles are not collected, you may find yourself needing to replace equipment more frequently. Additionally, if you are involved in the production of certain products, the presence of these particles can affect the quality of the output. This could lead to downtime caused by the need for repairs, which can be quite costly.

Therefore, the goal of using high-efficiency, high-quality filters is to optimize performance and reduce any potential downtime caused by accumulated particles downstream.

Hidden costs of budget air filters

Using budget air filters can come with hidden costs. These include disposal fees and the labour required for more frequent filter changes. Additionally, if the filters are not energy efficient—when using variable frequency drive (VFD) fans—there may be increased energy costs. This can also lead to more waste for landfills and additional expenses related to waste transportation and extra labour.

Air filter manufacturers must source their media from suppliers. These suppliers are responsible for manufacturing the media, a process that requires considerable energy for production and transportation to the filter manufacturers. This contributes to significant energy demands and higher carbon emissions. If you intend to save on energy consumption and reduce waste within your facility, it is essential to recognize that the supply chain also influences these savings. Addressing these factors can lead to a substantial positive impact on overall energy use and emissions.

Long-term cost savings with LCC for air filtration

When considering energy factors, it’s essential to focus on the lowest average pressure drop rather than the lowest initial pressure drop. Many air filter manufacturers advertise that they offer the lowest initial pressure drop, but when you install the filters, the pressure drop increases rapidly. This can lead to significant energy consumption.

It is best to have a filter that starts with a reasonably low-pressure drop—not necessarily the lowest—but one that maintains a consistently low-pressure drop throughout its lifespan. This approach will significantly reduce energy usage over the life of the filter. This is a crucial factor that can save you thousands or even hundreds of thousands of dollars, depending on the size of your building or operation.

The best LCC analysis is based on multiple real-life scenarios rather than just one. It should include three or four different scenarios, such as a building located near water and another in a farmland area, as well as challenges, such as having various types of contaminants. This approach provides a more accurate understanding of how long a filter will last in specific situations, for example a data centre situated in an urban area with high pollution levels.

With this comprehensive analysis, you can determine an average lifespan for the filter, and Camfil’s LCC will accurately predict filter performance within a narrow margin of variance.

An example of how to save money by investing in high-quality air filters is the comparison between spending $100 on high-quality filters versus the costs associated with replacing equipment or experiencing downtime because of using inexpensive, low-quality filters. For instance, shutting down production at a pharmaceutical company could result in losses of tens of thousands of dollars in a short period of time, depending on what is produced.

Using a filter that lasts nine months to a year instead of one that needs to be replaced every month allows you to allocate labour to other maintenance tasks.

When considering changeouts, it’s important to take into account all the factors involved. This includes unloading filters, transporting them to the designated area, and then disposing of the old filters.

To effectively compare your current filtration system with a new one, consider the following scenario:

Currently, you change your prefilters every quarter, your bag filters annually. If you decide to upgrade to a better filter, such as a Dual 9® that lasts between nine months to a year or a HiFloES® filter that lasts about two years, you can significantly enhance your system’s efficiency.

When conducting an LCC comparison, it’s essential to focus on the filter with the longest lifespan. In this case, the HiFlo ES® filter lasts for two years. Additionally, you should select a timeframe that can be evenly divided for both scenarios. For example, if the current filter bags last 18 months and the suggested product lasts 24 months, set the life cycle to 72 months. This would allow for three full changeouts of the current filters versus two full changeouts of the suggested product. By using this longer lifespan in your calculations, you can show more accurate estimates of savings over time.

If you switch to a Durafil® that can last three to four years, you will see cost savings in that time frame. Similarly, if you use a HiFlo ES® for two years, you will notice savings at that two-year mark. Alternatively, if you replace a traditional bag filter with a HiFlo® filter for just one year, you’ll also have a comparison point to analyze the savings against the current bag filter system.

It’s important to consider energy savings as well. If you are looking to save energy, you can input that as a parameter in the LCC software and get recommendations based on energy savings optimization.

Better efficiency

To improve efficiency, some may not see much difference between a MERV 13 and a MERV 14 filter. However, using proper life cycle cost (LCC) software can demonstrate the reduction in contaminants, which can be significant while not having a negative impact on energy consumption and waste. A 5-10% decrease in particles entering your building could make it worthwhile to upgrade to a higher-level MERV filter. The LCC software will clearly show you this impact.

Equipment protection saves money

By efficiently capturing dust, pollen, and other particles, high-quality air filters provide several important benefits:

· Minimize wear and tear: They reduce stress on sensitive components, extending HVAC equipment lifespan

· Prevent clogging and blockages: This ensures optimal airflow and system performance

· Reduce the risk of malfunctions: Higher-quality air filters protect against damage caused by airborne particles

Using inexpensive filters can lead to dirt accumulation on the coils. As a result, the heat transfer efficiency decreases, which means the pumps will need to run longer, which requires more energy.

Additionally, using cheap filters or those that quickly increase pressure drop can result in filter blowouts. This can require cleaning out the ducts and coils, as well as addressing any debris that may have blown down the system. Such situations can incur significant additional costs, including the need to replace equipment.

Corrective and preventative maintenance

In rare and extreme situations, particularly with small air handling systems, it’s possible to burn out the motor if proper preventative maintenance is not performed, especially when using an inexpensive filter. The issue often arises when there isn’t enough labour, leading to infrequent filter changes. People tend to forget to check the filters, especially if they have to go up on the roof.

If a filter only lasts a month and maintenance staff forget to check it for two to three months, it can become clogged and potentially damage the fan. In contrast, if you use a filter that lasts eight to twelve months, there’s a better chance that maintenance personnel will check it at least once during that time frame.

Balancing replacement cycles with budget constraints

Almost any LCC scenario that Camfil creates for customers can lead to overall savings in their annual budget. However, a common issue arises from where the budget funds originate. For instance, if a company has a sustainability committee with a designated budget aimed at reducing costs, it might allocate a specific amount to invest in energy-saving initiatives.

The challenge arises when you ask the maintenance manager to spend significantly more on a new filter with the promise of energy savings over a year. The reality is that energy savings do not come from the maintenance budget; they come from a different budget altogether.

It is essential to have the sustainability team, purchasing department, and maintenance manager on the same page. The goal is to explain that while the initial investment may come from the maintenance budget, the collective savings will benefit the entire organization. When everyone collaborates, the company will achieve overall financial savings.

How to use LCC to save money over the long term

After presenting Camfil’s LCC results, many customers rely on test banks to prove the results. In applications where the LCC time frame was based on years, it is possible to reduce the time required to prove the accuracy by intermittently comparing the pressure drop in the system, and estimating the future and using that estimation to compare to the results. You can also use the shortest life filter to prove the results once the filter has reached the life used in the LCC calculation.

The initial cost of an air filter is a very small portion of the total lifecycle cost. The most significant portion of the costs comes from other factors. Therefore, if you can make even a small reduction in any part of that 90% by using high-quality air filters, such as energy, which is the largest factor, you will save significantly more than if you simply focus on the initial cost.

· Savings can be realized when maintenance staff have more time for other more pressing concerns

· Equipment protection can lead to savings on capital expenditures for filtration equipment

· Money can be saved through significantly less energy usage by means of installing energy-efficient filters coupled with VFD-controlled fans

What are the sustainability goals in an LCC analysis?

Essentially, the goal is to optimize four key factors: achieving the lowest energy cost, minimizing waste, reducing labour time, and achieving optimal efficiency—not necessarily the highest efficiency. The aim is to find a balance among all four factors.

Furthermore, if you live in a region that relies heavily on fossil fuels or a small amount of nuclear power, opting for a premium filter instead of a cheaper one can have a significant impact on your overall carbon footprint.

The impact of energy generation on sustainability varies significantly. For instance, in regions like Quebec, where hydroelectric power is the primary energy source, the environmental impact is lower since hydroelectricity produces less harm to the environment. However, the scenario changes when you consider areas that rely more on coal, gas, or oil for energy. As you move towards these energy sources, particularly coal, the carbon footprint increases, especially when using higher-pressure drop filters.

Therefore, if you live in a region dependent on fossil fuels, choosing a premium filter over a budget filter can significantly affect your overall carbon footprint.

Green LCC

Camfil’s LCC software is built on actual in situ testing and applications, utilizing data from multiple test rigs and some on-site mobile systems. All test reports generated from these systems are integrated into the LCC software, making it possible to validate the performance of filters. This means it can be confidently stated that a filter will last for a specified duration based on real-life scenarios rather than laboratory tests.

Because the results are grounded in reality, when Camfil claims that a filter will last for a year, you can trust that it will actually last that long. In contrast, other software often relies on lab test reports or written summaries, which are not as reliable and could lead to ineffective or unsustainable outcomes.

This is why sustainability is emphasized in Camfil’s approach to LCC. The LCC software ensures longer-lasting products, resulting in fewer filter replacements and significant cost savings. Users can expect cost reductions of nearly 50% solely on filter expenses, in addition to benefits like improved air quality in schools and other public buildings, better energy efficiency, and more.

How Camfil’s LCC works

Basically, it’s as simple as selecting a few air handlers and inputting the air filters facilities managers are using. However, things can get a bit complicated when some air handling units use only prefilters while others have both prefilters and final filters. In this case, two or three different scenarios have to be created: one for the units with only prefilters and additional scenarios for the two-stage systems to compare the results.

The baseline information comes directly from the customer: what filters are currently being used and how often they are changed out.

Many people mistakenly believe that there is a straightforward correlation between efficiency and energy costs. They assume that using a higher efficiency filter will result in higher costs. That’s not necessarily true. You can utilize a much more efficient filter with a different design and still save a considerable amount of money. For example, if you use a MERV 14 bag filter that starts at around 0.6 inches and is changed out at 1 inch, the overall average pressure drop on a high-performance filter might be approximately 1.00 inches.

In contrast, if you install a Durafil filter with the same MERV 14 efficiency, it can last anywhere from three to five years in that system. It starts at roughly 0.3 inches, and by the time you change it out, it could be only 0.7 inches. Therefore, the average pressure drop will likely be about 0.45 inches, providing the same efficiency with a longer lifespan and lower energy usage.

When conducting a LCC analysis, the first thing you need to determine from the customer is what they want to reduce. Sustainability encompasses various factors such as waste, energy, labour, and more. The LCC analysis will illustrate the costs associated with each of these factors. There are times when you might encounter a customer who doesn’t prioritize energy efficiency as much as other issues. For instance, they may feel overwhelmed by their maintenance workload and prefer a solution that reduces labour time, as their team is already stretched too thin.

When running an LCC, you should tailor the results to align with the customer’s priorities. For that specific scenario, you would run several different scenarios and aim to provide the longest filter life for that application while maintaining efficiency. Should a customer wish to achieve the best overall scenario, the final report dollar estimate would be the deciding factor.

In standard applications, the Camfil HiFlo ES single-stage bag filter or the Camfil Durafil ES3 will consistently provide the optimum results.

FAQs on LCC and air filtration:

What is the role of filter efficiency in cost reduction?

Efficient filters help reduce energy consumption and extend equipment lifespan. High-efficiency filters also improve air quality, which can boost productivity and lower illness-related work absences. Additionally, efficient filters lower labour costs and protect infrastructure.

How does air filter life influence LCC?

The lifespan of filters significantly impacts the Life Cycle Cost (LCC). Fewer filter changes lead to lower expenses related to purchasing, installing, maintenance, and disposing of filters.

What costs are often overlooked in LCC analysis?

Inefficient filters can lead to increased energy consumption, resulting in higher utility bills. Poor air quality can also damage HVAC equipment, which may lead to a reduced lifespan for the equipment.

How can LCC be used to support green initiatives?

Lifecycle cost (LCC) analysis considers factors such as energy consumption and filter efficiency to identify the most energy-efficient air filtration solutions, ultimately reducing carbon emissions. This analysis also highlights the long-term environmental impact of various filter options, promoting the choice of sustainable and eco-friendly products. Additionally, it can identify opportunities for recycling and reusing filter materials, supporting a more circular economy approach.

Can LCC help in decision-making for filter purchases?

Life Cycle Cost (LCC) analysis can be an invaluable tool for businesses when deciding on filter purchases. By evaluating the total cost of ownership (TCO), companies can optimize their air filtration systems and achieve long-term cost savings. Key factors to consider include the purchase price, energy use, maintenance expenses, filter lifespan, and environmental effects. Solutions can be tailored to the specific needs of customers.For companies that use tenders to purchase filters, the RFQ can be based on total cost over a longer period of time as opposed to initial price…. e.g., total annual filter cost not to exceed $XXXX.

How does LCC benefit multi-facility operations?

LCC (Life Cycle Costing) enables a standardized approach to filter selection across multiple facilities. By centrally analysing LCC data, organizations can identify cost-saving opportunities and optimize filter performance throughout their entire network. This centralized procurement takes advantage of economies of scale.

Consistent filter performance and extended filter life help minimize downtime across facilities, thereby improving operational efficiency. LCC provides data-driven insights that support informed decision-making regarding filter selection and maintenance schedules.

Leveraging real-world data, Camfil’s LCC enables accurate predictions of future expenses, empowering users to make informed decisions. By optimizing filter selection for specific applications, LCC helps identify the most cost-effective solutions. Additionally, LCC promotes energy efficiency and sustainable practices, contributing to a greener future.

To find out more about how to choose the right air filter, or get a complimentary IAQ and air filtration site survey, please use this contact form.

About Camfil Canada Clean Air Solutions

For more than 60 years, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. Read more about Camfil Canada

##

*With information provided from an interview with air filtration expert Berni Baier

Media Contact:

Phillip Ilijevski

Camfil Canada Inc.

T: 437-929-1161