Summary:

In this blog post air filtration Segment Leader for Molecular Contamination Control, Victor Rengel, describes corrosion, explains which processes and artefacts are most susceptible to corrosion, and shares how to prevent corrosion in Canada.

Most Canadians have flown in a commercial airplane, seen a natural monument, visited a museum, or accessed a file on a work computer via the help of a data centre. These activities have one thing in common: they are all vulnerable to corrosion. The negative effects of corrosion are much worse than most people realize. According to the National Association of Corrosion Engineers (NACE), corrosion caused $2.5 trillion worth of damage in 2013 alone, with costs continuing to rise as corrosion remains largely unaddressed1.

It is evident that the process of corrosion must be better understood, and it is important that building developers and inspectors be aware that in some situations, molecular filtration can be used to prevent it.

What Is Corrosion? Corrosion Examples Explained

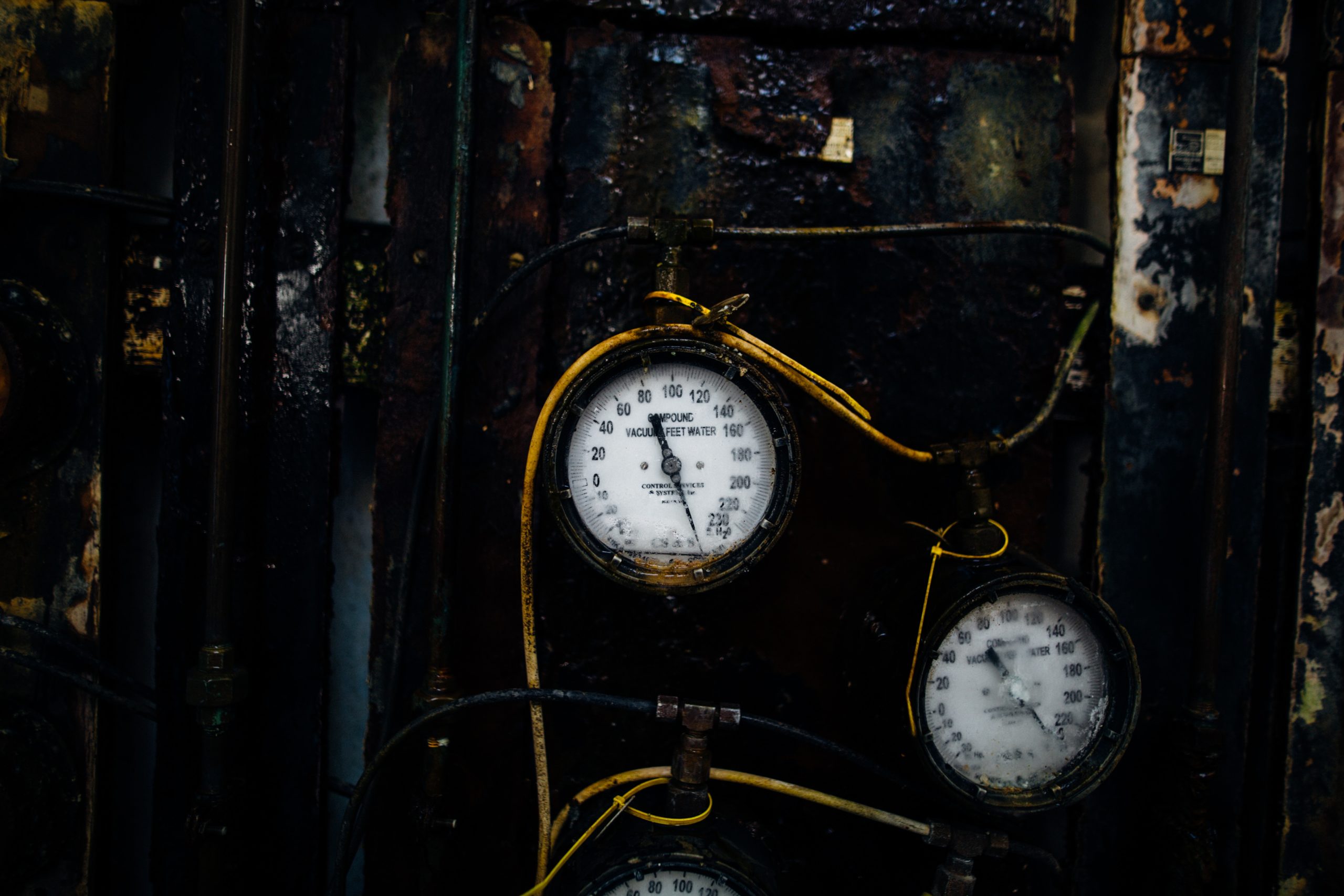

Corrosion is a process in which a material decays due to a chemical reaction with its environment. A metal, for instance, begins to corrode when it comes in contact with a gas or liquid. This corrosion process can be accelerated by exposure to warm conditions, acids, and salts.

One common example of this is the oxidation of iron, which is referred to as rust. When iron comes into contact with oxygen from the air and with water (which may be in the air or from another source), a chemical reaction occurs to form a more chemically stable compound. However, particularly in the case of rusted iron, this chemically stable compound is much less physically stable, and is prone to flaking away and crumbling.

What Contributes to the Corrosion of Canadian Materials?

Increased air pollution levels bring about corrosion due to the mixture of particles and gases contained within it. Three agents present in air pollution that contribute heavily to corrosion are particulate matter (PM), sulfur dioxide (SO2), and hydrogen sulfide (H2S).

Particulate Matter

Air pollution contains particulate matter (PM), which can be highly corrosive. The liquids and solids contained in PM, including black carbon and salts, can interact with the molecules within metals and create a chemical reaction.

Sulfur Dioxide

Sulfur dioxide (SO2), is one of the biggest contributors of corrosion. Generated by power plants and vehicle emissions, SO2 can be particularly aggressive towards the copper used in electronic equipment. Not only this, but SO2 also damages foliage and inhibits their growth2.

Hydrogen Sulfide

Another common acidic gas is hydrogen sulfide (H2S). It is a colorless gas known for its pungent “rotten egg” odor at low concentrations. It is corrosive, extremely flammable and highly toxic.H2S is used or produced in a number of industries, such as: oil and gas refining, mining, and pulp and paper processing3.

Other gases that can produce corrosion issues are Chlorine, Nitrogen Oxides (NOx), Hydrogen Fluoride, Ammonia and Ozone.

What Happens if Corrosion is Ignored?

To illustrate the potentially catastrophic impacts of failing to prevent corrosion, let’s look at a real world example:

In 2012, a mall in Northern Ontario partially collapsed, resulting in the death of two women and injuring several others. In a forensic study commissioned by the Ontario Provincial Police (OPP) as part of its investigation, investigators found that the corrosion of the structure’s steel supports from years of exposure to water and road salt caused the collapse4. Had the development supervisor and building inspectors took action to prevent the corrosion, the collapse may not have occurred. While this is an extreme scenario, this situation demonstrates the possible outcome of ignoring corrosion. Although molecular filtration will not be able to prevent such issues, there are just as severe issues that it can help alleviate such as circuit board failure shutting down a complete production line, irreplaceable art work and statues that can never be restored, etc.

Aside from certain raw materials such as metal, there are a number of items and equipment that are most susceptible to corrosion.

What Items and Equipment Are Prone to Corrosion?

All man-made materials are subject to corrosion. However, the items and equipment that can corrode easily are: sensitive electronics, server rooms and data centers, and culturally important artefacts5.

Sensitive Electronics

Automation is used in manufacturing facilities globally. Most industries are typically somewhat reliant on electronics and/or electrical control equipment, if not, completely reliant. In industries that have complex processes, the air lingering in the facility may be contaminated with acidic gases. Air is most likely to be contaminated in the oil and gas industry, pulp and paper, mining, and wastewater treatment6.

Server Rooms and Data Centers

Data centers are dynamic environments where upgrades and equipment changes happen often. This leads to a potential introduction of airborne contaminants into the environment. Data centers also house chlorine that can be emitted from PVC insulation on cables if temperatures increase too high7.

Culturally Important Artefacts

Critical factors for air quality in museums and galleries include temperature, relative humidity, lighting, dust, molecular (gaseous) pollutants, and pests. Molecular pollutants can have devastating effects on important artefacts and paintings. For example, SO2 blackens old paintings, nitrogen corrodes bronze and stone sculptures, and ozone deteriorates paper and other organic materials8.

How Can Corrosion Be Prevented?

There are many clean air solutions that provide maximum removal of corrosive molecular contamination. The CamCarb VG300 and CamCarb VG440 from the CamCarb family of molecular filtration products are V-cell filters for the control of acidic gases. The VG300 format is best suited for moderate duty (normally make-up air) applications and the VG440 is best suited for light-duty (recirculation air) applications.These plastic modules feature a unique approach to filter clamping and sealing with a compression gasket to ensure that the efficiency of the molecular media is not compromised by internal bypass. The modules may also be used as replacements in many traditional side and front-access housings, and they are packed in cartons with polyethylene liner to preserve media condition.

For higher contaminant concentration applications, ProCarb VDBs is designed to ensure the very highest levels of performance. Normally this means following standards and achieving the requirements of ISA S71.04:2013 class G1 or a similar category of air quality from IEC 60721-3-3.

If portability or plug-and-play solution is required, the CamCleaner Vertical from our molecular air cleaner line is a free-standing mobile air cleaner designed for corrosion control applications in heavy process industries.

There are a variety of factors that determine which clean air solutions work best for corrosion control. Be sure to contact an experienced air filtration consultant to find choices right for your building.

About Camfil Canada Clean Air Solutions

For more than half a century, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. We firmly believe that the best solutions for our customers are the best solutions for our planet, too. That’s why every step of the way – from design to delivery and across the product life cycle – we consider the impact of what we do on people and on the world around us. Through a fresh approach to problem-solving, innovative design, precise process control, and a strong customer focus we aim to conserve more, use less and find better ways – so we can all breathe easier.

The Camfil Group is headquartered in Stockholm, Sweden, and has 33 manufacturing sites, six R&D centers, local sales offices in 30 countries, and about 4,800 employees and growing. We proudly serve and support customers in a wide variety of industries and in communities across the world. To discover how Camfil Canada can help you to protect people, processes and the environment, visit us at www.camfil.com/en-ca/.

##

Media Contact:

Holly Gardner

Camfil Canada Inc.

T: 437-929-1161

F: Follow Camfil Canada on Facebook

L: Follow Camfil Canada on LinkedIn

T: Follow Camfil Canada on Twitter

Resources:

1https://www.appmfg.com/blog/4-galvanic-corrosion-statistics-you-should-know

2https://www.camfil.com/en-ca/insights/electronics-and-optics/what-are-the-effects-of-corrosion

3https://www.osha.gov/hydrogen-sulfide

5https://www.camfil.com/en-ca/insights/electronics-and-optics/what-are-the-effects-of-corrosion

6https://journal.uptimeinstitute.com/solving-air-contaminant-problems-data-centers/

8https://www.camfil.com/en-ca/insights/air-quality/museum-air-quality-blog-post