Molecular filtration is being used more than ever in Canada to remove volatile organic compounds, highly toxic gases, and odorous contaminants. It can protect people and equipment in buildings or be used for corrosion control. This article will discuss different types of molecular filters and their various applications. We will also discuss choosing the right kind of filtration for your organization.

What is a molecular air filter, and what does it remove from the air?

Molecular air filtration uses certain types of media that we call ‘absorbent’ in air filters, such as activated carbon filters, to remove contaminants from the airstream in gas form. Some pollutants can be harmful to people and processes. The molecules are adsorbed and get inside the air filter’s media and are thereby removed from the environment. These media are usually porous and have a very high internal surface area, which is used to adsorb a high concentration of contaminants.

Major uses of molecular filtration are:

- Odour control: removing odorous gases before they get into occupied spaces

- Comfort: some people are more sensitive to specific gases, so the removal of those contaminants for improved air quality is important

- Removing highly toxic gases: hydrogen sulphide, for example, is a gas that, in high concentrations, can be lethal. Especially in the industrial sector, we find molecular air filtration applied to get rid of this highly toxic gas and other highly toxic gasses

- Protecting equipment or processes, corrosion control: Removing acid gases in a wastewater treatment plant and or paper mill. Also commonly found in oil and gas refinement

- Cultural heritage: e.g. protecting priceless paintings, a historic sword, or very important archives

Which volatile organic compounds (VOCs) can molecular/activated carbon air filters remove?

There are thousands of volatile organic compounds found in any environment. The most common sources are VOCs released from furniture. Other sources include paint on walls, markers used in schools and offices, and perfumes. Cleaning products are major sources of VOCs, especially in processes that use heavy cleaning agents. Activated carbon air filters are great at removing these and other VOCs.

Can a MERV-13 or MERV-14 air filter remove volatile organic compounds (VOCs) from the air?

VOCs are gases, so any high-level MERV air filter won’t remove them. Molecular air filtration needs to be applied to get rid of VOCs. PM1, PM2.5, and PM10 particles can be removed by the appropriate MERV-rated air filters, and molecular air filters remove VOCs and other harmful gases. It is imperative to use both in tandem. HEPA air filters remove at least 99.97% of particulate matter, but not gases.

If poor indoor air quality is caused by a gas, molecular air filtration is necessary.

Why are they called molecular air filters and not simply “carbon air filters?”

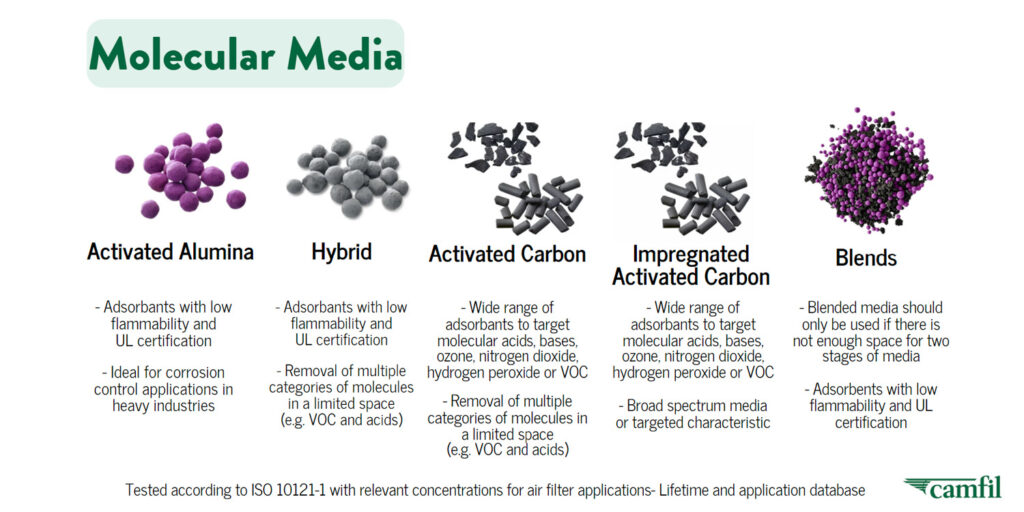

They are called molecular air filters because they use molecular adsorption to bond with gases and keep them out of the air. There is more than a single type of media. Activated carbon is the most common and will work for 90 to 95% of the gases that we know of, but there are other types of media that have different base materials, such as aluminum, that are very effective in dealing with acid gas.

Potassium permanganate is added to aluminium and such media does not use carbon. People use the term “carbon filtration” to describe molecular filtration. That term is not technically accurate and not descriptive of the actual media required.

There are two types of activated carbon air filters. One uses coal as a base, and the other uses coconut shells. In this case, the molecule gets inside the carbon and then sticks to the surface. Molecular air filters have channels, and the molecules to be removed go through the macropores and micropores. Gas gets into the micropores and gets compressed, keeping it in the pore.

It’s imperative to place a particulate air filter with its particulate-removing media in the first stage of air filtration and place a molecular air filter with its molecule-removing media in the second stage of the process.

How effective are molecular air filters and activated-carbon air filters at removing odours?

They are highly effective for most of the gases we know of, but there are a few contaminants that are more difficult or impossible to remove. High-quality air filters with high-quality media that have been designed and tested properly are far more effective at removing odours than typical molecular air filters.

What types of odours are typically removed by molecular/activated carbon air filters?

A good example of odours removed by molecular air filtration is in cannabis cultivation. It’s an odour that is not highly toxic or harmful, but it’s certainly something that companies in the cannabis cultivation industry must be concerned with. Companies don’t want the odour to escape the facility. People in the vicinity may not always consider the odours to “smell bad,” but they are powerful odours nonetheless. Health Canada advises cannabis producers, especially those situated near residential areas, to follow guidelines to prevent odours from affecting the environment.

Community relations

For example, there is a cannabis production facility in Southern Ontario, and it’s very close to an area with homes downwind. These companies prefer to be in more remote areas so odours don’t cause disturbances. Still, they must be closer to more populated areas with proper infrastructure and better access to labour.

The last thing cannabis producers want is for residents to complain to local, provincial, and federal governments about unwanted odours coming from cannabis production facilities.

Industries which can benefit from odour-control molecular/AKA carbon air filters

Cannabis cultivation industries, wastewater treatment plants, chemical treatment plants, battery production facilities (by-products), the pulp and paper industry, and others can benefit from molecular or activated carbon air filters.

Airports filter our jet fuel gases not only from the tarmac but also from ground transportation. Cars, buses, and taxis are in and out of airports 24 hours a day, dropping off people, picking up passengers, etc. The most common contaminants exhausted are sulphur dioxide and nitrogen dioxide. “Ambient NO2 exposure may increase the risk of respiratory tract infections through the pollutant’s interaction with the immune system. Sulfur dioxide (SO2) contributes to respiratory symptoms in both healthy patients and those with underlying pulmonary disease. Controlled human exposure studies have demonstrated that experimental SO2 exposure causes changes in airway physiology, including increased airway resistance.” –Source: NIH

What types of air filters are there in molecular air filtration?

There are three major product families in molecular air filtration.

1. Light-duty comfort air applications, e.g. City Family

2. Medium to heavy duty applications, e.g. Cam carb

3. The pro-level family of deep bed air filters, e.g. Pro carb ( commonly known as scrubbers), used for applications where the gas concentrations are very high and/or high removal efficiency is required

Some combination air filters perform both particulate air filtration and molecular air filtration. They could be bag filters, pleated filters, or activated carbon filters where carbon is embedded in the air filter. The carbon or other molecular properties are embedded within two layers of media. This is a combination air filter that will remove particulate matter and gases.

Other products include the cam carb line and the pro-carb line, where the media is installed in the filter. It could be a plastic container or other filter shapes such as a cylinder, a panel, or even a large compartment that will hold various amounts of bulk carbon. There are some applications where if you don’t include a large amount of molecular media, air filtration would work, but only for a very short period.

With industrial applications, the optimal solution is to use air filters lasting no less than two years -not having to replace the media very often as it can be very time-consuming- labour intensive, costly, and very messy.

What is an example of when gas concentrations are very high and/or high removal efficiency is required, and deep bed air filtration is used?

A good example is in the use of chlorine removal or foam manufacturing. When there is a highly toxic gas, for example, Toluene diisocyanate (TDI) “used in the production of polyurethanes. TDI is also utilized in the manufacture of coatings, sealants, adhesives, and elastomers” (from Americanchemistry.com) which needs to be exhausted from the facility, high removal efficiency needs to be achieved to have a zero, or close to zero concentration at the outlet.

Another good example of a high removal efficiency use is a corrosion control application in case we want to protect electronic equipment from acid gases. “Corrosion of electronic process control equipment can cause disruptions in production leading to lower productivity and lower profitability – this can be expensive to fix.” One reason for corrosion is that chemical reactions between liquids and solids create airborne contaminants such as corrosive gases. You can invest in high-efficiency air filters to improve indoor air quality, eliminate harmful pollutants contributing to corrosion processes, and protect your switchgear and control rooms.

Recommendations for molecular, activated carbon air filters and air purifiers

Everything depends on the application. Molecular air filter expert Victor Rengel recommends the city family line for light-duty applications. Still, in other applications requiring more robust air filtration, it is best to consult an air filtration expert to determine each specific need. For example, determining what type of structure would work best for each application and how much media would be needed for each area. An air filtration expert will be able to advise any business on their filter needs for each application and will also be able to advise on how to reduce energy consumption, cut labour costs, and give you the longest-lasting air filters available.

What is the process of adsorption when it comes to air filtration?

It’s when molecules in the airstream defuse, get into the molecular media’s internal space and stay there. Basically, it pushes gases into holes in the media.

Air filtration expertise is a crucial element when planning, refurbishing, or reconstructing an air filtration system. It’s best to ask for specific recommendations from an expert based on robust testing and experience in the laboratory and the field on actual sites that use molecular filtration. Also, performance must be backed up by data from a molecular filtration lab.

Molecular air filtration requires a different type of molecular media and testing down to specific gases at specific concentrations.

Finally, ask for molecular lab services to test molecular media after it has been used. This is very important as it’s the best way to estimate the life expectancy of the media inside the air filters. For example, replacing filters too early or too late is not desirable, as this can be costly.

To consult with an air filtration expert on the topics covered in this post or for further information, please use this contact form, and an air filtration expert from Camfil Canada will answer any questions you may have.

About Camfil Canada Clean Air Solutions

For 60 years, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. Read more about Camfil Canada

##

Sources:

Media Contact:

Phillip Ilijevski

Camfil Canada Inc.

T: 437-929-1161