Choosing the right commercial or industrial-grade air cleaner can be a challenging endeavour. There are many things to consider, such as the size of your room or building, the type of pollutants you want to remove, air filter efficiency, the noise level of the air cleaner, how much energy the filtration system will consume, and the cost. There are many uses for industrial/commercial-grade air filters. This article will help you make informed decisions by guiding you through the uses and many parameters involved in selecting the best commercial or industrial air cleaner for your organization.

What is an industrial/commercial-grade air cleaner?

An industrial/commercial grade air cleaner is designed to improve air quality in environments with a higher level of contaminants than usual, such as electric vehicle plants, warehouses, cannabis production, and food and beverage production facilities. Industrial air cleaners are unlike air purifiers designed for home environments or small spaces. They are explicitly designed to improve air quality in larger spaces. The highest-quality air filtration systems are also designed to use less energy.

In an industrial setting like a wastewater treatment plant, airborne particulates and volatile organic compounds (VOCs) and other gases are of concern. Some industrial/commercial air cleaners are designed to remove particulate matter with a particulate filter and remove VOCs using a molecular filter, such as an activated carbon air filter.

Molecular filtration is different from particulate filtration

Matter that can be filtered through molecular filtration is about 10,000 to 100,000 times smaller than matter that can be removed through particulate filtration. Molecular filtration uses a different filtration technique called adsorption—the molecules are drawn into pores in the media.

Industrial and commercial air cleaners are designed to filter out airborne dust contamination, harmful particles, and VOCs to provide the best air quality, protect processes, and provide a better working environment for employees and customers. It can also maintain purity for pharmaceutical products and keep contamination out of semiconductors.Industrial/commercial-grade air filters should feature robust construction, powerful motors, and customizable features. Once you plan to place equipment in an industrial setting, depending on the processes taking place, the environment is a big factor in how the unit should be designed and constructed. If it’s not constructed with 14 gauge or 16 gauge galvanized steel, a reduction in unit lifetime, or damage to the unit can occur due to the presence of heavy equipment and the workload air cleaners are subjected to in the environment.

How to choose the right industrial or commercial air cleaner:

- Start by measuring the height, width and length of your room to find the cubic footage, then divide that by 60, and this will determine how much airflow is needed for one air change per hour. Multiply this by the number of air changes you want to achieve per hour (decided by an air filter specialist and your organization), and this will determine the number and size of the units you require.

- It’s essential to be aware of the specific type of replacement filters for the unit and how often they need to be changed. Filters are vital in maintaining your air cleaner’s performance and efficiency. Depending on the model and usage, you may need to replace filters every few months, once a year, or even every five years.

- For longevity and efficiency, design and quality matter. Poorly designed air cleaners are not designed to last. They are designed with inferior materials and media to keep costs low. Make sure you are getting what you pay for. Ask for test results certifying performance before purchasing an air cleaner.

How to reduce air cleaner noise

Some air cleaners are relatively quiet, even at full settings and speed. Determine the maximum decibel rating you are willing to tolerate in your space and match that to the specs of the air cleaner that you are seeking to purchase.

The fan speed of your air cleaner affects how much noise it makes and how much air it circulates. Adjust the fan speed depending on your needs and preferences. If noise is a factor, run more units at a lower speed, this will result in a reduction of the overall decibel level.

Customization of industrial/commercial air filters is an important feature

Customization is also essential because commercial settings are unlike residential settings, where a small air cleaner can be placed in the centre of a living room. Make sure that the unit is positioned correctly to ensure good accessibility.

Some air cleaners can be customized to tie into building automation systems (BAS), building management systems (BMS), or building energy management systems (BEMS). These systems centralize control of various systems such as lighting, heating, cooling, and energy use.

Multi-stage industrial/commercial air filters

Industrial air cleaners can utilize multiple stages of filtration, depending on the work environment. Commercial and industrial air filter expert Abhishek Arora says, “For example, an air cleaner can have a prefilter and a HEPA filter, followed by a molecular filter, or a MERV-8 or MERV-9 prefilter followed by a secondary MERV-14 filter, and a HEPA filter in the final stage. Which to choose depends on the nature of the environment and what kind of particles are in the environment. Based on that, we can recommend the appropriate filter selection.”

A three-stage air filtration system may be necessary in a heavy dust environment, such as a bakery, where a lot of dust is generated. In these applications, the particles can be so minute that HEPA filters need to be installed to remove submicron particles.

Commercial air cleaners and building occupant health and well-being

Poor indoor air quality in the workplace can lead to increased sick days and decreased productivity due to inadequate air filtration and the presence of pollutants like mould, allergens, VOCs, and other harmful particles. This can negatively impact employee health and productivity in commercial and industrial spaces. Poor indoor air quality can also cause many health problems, from mild allergic reactions and itchy eyes, to more serious health issues such as cardiovascular disease or cancer.

Case studies have been published showing that clean air positively affects cognitive function.

Can ozone be released by air cleaners?

There is a potential for air filtration systems to release ozone if you are using an air cleaner with electrostatic properties. Arora recommends asking for original equipment manufacturer (OEM) test reports. He advises, “Make sure there are no by-products of the electronic air cleaning system being released that could harm human health.”

Do you recommend electronic air filters?

The major disadvantage of electronic filters is the upkeep involved. You have to clean electronic filters frequently, whereas when you use a filter based on mechanical filtration techniques like inertia, interception, straining and diffusion, that filter will last longer. You don’t have to maintain it as much or monitor it as much as an electronic filter. Mechanical filters just need to be changed out when the pressure drop reaches its maximum desired level.

Use a filter that lasts the longest, provides you with the lowest average pressure drop, and uses mechanical filtration techniques built into its media to provide you with the best filtration performance for your commercial property or industry.

Arora says, “We see electrostatic precipitators that claim a MERV-13 or MERV-14 efficiency in the field. However, it is important to note that they cannot be tested as mechanical filters can, with ASHRAE test dust. It is, therefore, impossible to get a MERV rating from these filters. Electrostatic filters are effective filtration devices because of an artificially applied electrostatic charge. Once those filters accumulate dust, the electrostatic charge dissipates, and the efficiency of that filtration system drops.”

How to evaluate the long-term cost of air cleaners

Electronically commutated motors, or EC motors, used with mechanical filters, will maintain their efficiency through the life of the filter and give you the longest average lifetime. Also, while premium air filters initially cost more, they will save you money in the long run due to their energy efficiency and longevity. You can use this cost calculator to determine life cycle cost

How vital is installation and integration with current air filtration systems?

Arora states, “Air cleaners are supplemental systems. For example, when the pandemic began, many organizations didn’t have the footprint or the fan capacity in their HVAC systems to incorporate heavy HEPA filters or higher-efficiency filters because they were concerned with pressure drop in the primary system. Air cleaners can greatly aid existing HVAC systems. You are not taxing your primary system. It’s a plug-and-play system whereby you have it on the room side. It’s portable, it has casters, and you can move it around from room to room if needed.”

Arora also advises, “Make sure the OEM provides you with the maximum static pressure that the air cleaner can withstand when it comes to ducting it because there are a lot of times when customers use the air cleaner with excessive ducting and bends that eat away at the airflow.” If you plan on ducting an air cleaner, follow OEM guidelines.

Air cleaners play a crucial role in wastewater treatment plants

Odour control in wastewater treatment plants is crucial due to the “rotten egg smell” caused by gases. These odours can affect worker health and safety and cause inconvenience to nearby residential areas. Use molecular filtration to control odours.

Safety Hazards Protection -Exposure to certain gases can be hazardous to health. Prolonged exposure to hydrogen sulphide can result in headaches, weakness, and even coma, according to the CDC. High-quality air cleaners reduce safety risks.

Equipment protection -air cleaners protect by limiting harmful gases in the supply air to control rooms, minimizing equipment damage and maintenance downtime.

Relations with surrounding communities –High-quality air cleaners can help reduce complaints by reducing wastewater treatment plant odours.

Air cleaners in the pulp and paper industry

Combating corrosion -Pulp and paper production involves aggressive chemicals that can corrode equipment. This can lead to unplanned shutdowns and a loss of profitability. Air cleaners help prevent equipment failure by removing pollutants. Supply air (outdoor air) may be contaminated with acidic gases. These gases can damage equipment and cause failure due to corrosion. Air cleaners remove these gases.

Remove contaminant gases –Hydrogen sulphide, sulphur dioxide, mercaptans, chlorine oxide, and ozone are often present in processes. These gases can be removed with molecular filtration.

Industrial air cleaners are suitable for room pressurization and recirculation systems. They can be utilized to solve indoor air quality problems in factories.

Advanced air filtration solutions for cannabis facilities

Particle Capture –Workers may have respiratory problems due to dust and allergens produced during processing. Harmful particles can be removed using air filters with ASHRAE Standard 52.2 and Appendix J designation.

Odour Control –Activated coconut shell carbon is the best solution for longevity and odour removal effectiveness.

Air cleaners must remove dust particles, odours, and gases, providing a comprehensive solution for air quality problems in cannabis cultivation facilities. Read more on air filtration for cannabis cultivation facilities

Proper installation of air cleaner equipment is crucial

When you have a project, it is best to find a reputable company to do the installation. Ask the right questions, and have all the information upfront before choosing an air cleaner, because it can save you a lot of time and money down the road.

Airflow capacity

It is essential that you consult with an air filtration expert to select an air cleaner with adequate airflow capacity. For example, if you choose an air cleaner and its stated capacity is 500 CFM, confirm that it is an in situ measurement with the original equipment manufacturer (OEM). Some companies may state that the air cleaner’s capacity is 500 CFM, but it could be a reading without the filter inside. There is no point in specifying CFM for any air cleaner without the filter.

Positioning of air cleaning units

A good technique for positioning an air cleaning unit is to blow out two-thirds of air for every one-third of air you draw in. This is sometimes referred to as the Racetrack or Circular effect.

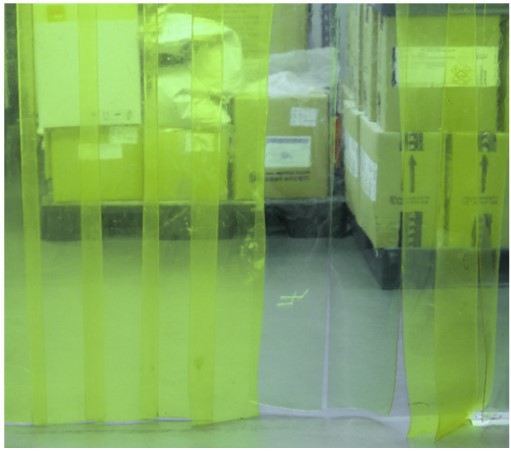

Strip curtaining for spot air cleaning

Strip curtaining can also be used in welding or other spot applications. In this case, an air cleaner can be used for localized contamination control, where more contaminants are generated mostly in a spot area.

Strip curtaining allows for controlling the air quality in a small area within a large building

Integration of smart technologies for real-time monitoring and control of air cleaners

Many indoor air quality (IAQ) monitoring systems are available. These monitoring devices can be connected to the air cleaner, provided they have the capability to communicate with each other. For example, an air quality monitor may register a ‘moderate’ reading, but ideally, an air quality monitor should show air quality improving over time with the introduction of clean air solutions. Arora says, “The monitoring device picks up PM1 and PM 2.5 particles, and it sends that data onto an online platform where you can see the reduction in these harmful particles from your environment over time, while using the air cleaner.”

Sustainability and Eco-friendly options for air cleaners

Arora states, “By making air filters that last the longest and provide you with the lowest average pressure drop, give you the best energy savings, and produce less waste, sustainability is not something we do; it’s what we are. We provide hardware and filters for very small footprints to do more with less. We also provide environmental product declarations for our products to show the carbon (CO2) emissions that go into manufacturing our products. Being eco-friendly is something ingrained in our DNA as an organization.”

Camfil also does simple things like using brown corrugated boxes for all filters and water-soluble or environmentally-friendly ink to print labels on the boxes.

Future trends in industrial/commercial air filtration

A prime example of a positive future trend in air cleaners is a smaller footprint and a lighter design. Arora says, “We recently introduced a HEPA filter weighing only 20 lbs. This is only one-third of what many filters used in similar settings weigh. A typical commercial or industrial HEPA filter can weigh up to 60 pounds. The Absolute VG is not only light, but it also features the lowest average pressure drop of any HEPA filter on the market.” A lighter filter is much easier to handle when replacing air filters and disposing of them. It also creates less waste and reduces transportation loads, reducing carbon footprint.

Camfil is constantly working on innovative designs for air filters that reduce waste, last longer, and use less energy.

Camfil recently released the CamCarb XG, A conical, corrosion-resistant molecular filter filled with activated alumina or activated carbon. It features versatile gas-phase air filters installed in supply, recirculation, and exhaust air systems for commercial, industrial, and process applications. The design provides the lowest total cost of ownership for the removal of corrosive, odorous, and irritant gases.

To consult with an air filtration expert on the topics covered in this post or for further information, please use this contact form, and an air filtration expert from Camfil Canada will answer any questions you may have.

About Camfil Canada Clean Air Solutions

For more than 60 years, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. Read more about Camfil Canada

##

Sources:

Abhishek Arora, Canadian air filtration expert

Center for Disease Control (CDC)

American Society of Heating, Refrigerating and Air-Conditioning Engineers. (ASHRAE)

Media Contact:

Phillip Ilijevski

Camfil Canada Inc.

T: 437-929-1161