Written by Air Filter Expert Jon Holmes and Phillip Ilijevski

Air filter changeout season can be a hectic time, but it doesn’t have to be. Dirty, dusty filters; no one likes changing them, but filters play such an important role in tenant comfort and building efficiency. Unfortunately, often building operators aren’t getting the best value out of their filters because the filters are either changed too soon, resulting in increased labour and filter costs, or some property managers overextend the filter’s service life to save money, but unfortunately, they pay an energy penalty to do so.

Waiting too long to change an air filter could damage HVAC equipment and result in poor indoor air quality. There are better ways to do it. It is important to understand when to change your air filters and why timing is essential. In this article, we will provide insights into the best practices.

“I change my filters when they ‘look dirty.’”

When and why should I change my HVAC air filter (if not when it just ‘looks dirty’)?

All too often, filters are changed prematurely because the filter “looks dirty,” but many still have service life left. As a comparison, fast lube shops show customers the outside of the car’s air filter to upsell a replacement, but the dirty upstream side of a filter is a poor indicator of when to change it.

No person visually, no matter how experienced, can accurately estimate how much life a used filter has left. If any visual metric is to be used, the downstream (clean air) side of the filter should be the only visual cue, but pressure drop is the only accurate way to properly determine filter performance and life expectancy. As long as a filter maintains its MERV-A efficiency, air quality does not further improve with more frequent air filter changes.

I change my filters based on time

-Should I always change my air filters on a set schedule, or is there a better way?

Air filters face many pollutant challenges that vary from year to year. These challenges may include seasonal changes, smog levels in the area, proximity of construction to buildings, and intensity of wildfires, among others. As a result, changing filters based solely on time could lead to premature filter replacements, which can increase waste and costs, or keeping filters in the air handling units for too long, which could restrict airflow.

Depending on the air handling equipment, restricted airflow can either reduce air movement or increase energy consumption, as fans have to work harder to pull air through clogged filters. Despite this, many operators follow a strict rule of replacing filters every three months. However, just as technology has advanced to change a car’s oil based on the number of kilometres driven instead of at a certain time interval, air filters should also be replaced based on their effectiveness in protecting the air handling unit and providing clean indoor air.

How do I know when I should change my filters if not based on visual interpretations or time?

It depends on what the end goal is – is it to save energy or time? The first step is to either get a pressure differential gauge, or ensure existing ones are in working order. Because If you don’t track it, you can’t manage it.

Energy: If the facility has variable frequency drives (VFDs) in place, it is typically cheaper to replace the filter at approximately double the initial pressure drop rather than waste the energy to push air through a pressure-loaded filter. For example, at $0.10/kWh, at 500 FPM velocity, operating for 12 hrs/day, it will cost approximately $17 in energy per 1/10th of an inch of water gauge per filter opening, per year. For a building with one hundred 24″ x 24″ pre-filters, this amounts to $8750/year in energy at just a ½″ pressure difference.

Often, building operators will leave an air filter in longer to reduce filter costs. However, for example, to save a $6 air filter by running it to 1″ w.g., it costs the facility an extra $87.50/filter in energy usage. Instead of saving money, they are actually overspending on energy.

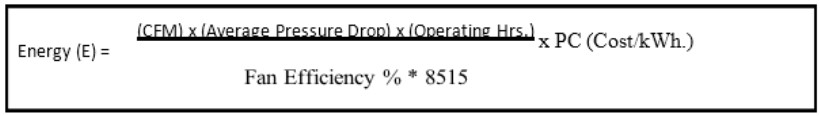

Here is the engineering formula to justify the quantification:

Sustainable, high-performance air filtration can help you achieve your net zero goal

Save labour time by using high-quality air filters

On constant speed fans, there won’t be as much energy savings specifically from changing the filter at double the initial pressure drop, but there will be an increase in airflow. There may be energy savings as the coils won’t have to work as hard to maintain temperatures because of the increased airflow in the facility. Five minutes per filter of labour can be reallocated to higher priority tasks if the filter were to be changed at a maximum 1”w.g. should airflow demands be met. This not only saves time and labour costs, but it also ensures that the HVAC system is running efficiently. By reallocating this labour to more important tasks, the overall productivity of the facility can be increased. Additionally, by maintaining proper airflow and changing filters at the appropriate pressure drop, the lifespan of the HVAC system can be extended, further reducing costs in the long run.

Which way should I install HVAC air filters?

Pleats and pockets should always run vertically (up and down)

When ordering filters with different height and width, it is important to ensure the pleats and pockets are running along the vertical size. For example, if the frame where filters are installed is 24H x 20W, but the filters ordered are 20Hx24W, they can be installed in that frame, however, the pleats and pockets would be oriented horizontally, leading to worse performance and potential for lower quality pocket filters to oscillate enough to make holes in the filter. To prevent this issue and ensure optimal performance, it is crucial to always match the direction of the pleats and pockets with the vertical size of the frame. This will guarantee that the filter functions effectively and efficiently, maintaining air quality and preventing any potential damage such as when an air filter blows out and fragments enter the air filtration system. Therefore, double-checking the dimensions and orientation of the filters before installation is essential in order to avoid any complications or issues down the line.

How can your business benefit from using high-quality air filters?

These days, building operators are tasked with more and more projects, in addition, everyone is under pressure to reduce costs. To retain tenants, building operators are also tasked with the challenge of keeping the air temperature and quality at a perfect level for everyone, a near-impossible feat with economy air filters.

The bottom line is that changing both prefilters and final filters based on pressure drop measured by a Magnehelic gauge rather than an arbitrary time or visual metric will result in happier tenants, lower filter costs, lower energy bills, and lower waste costs while being able to reallocate labour. Staff can focus on tenant engagement and other more value-added projects.

Ultimately, the best value air filter is one that maintains the lowest average pressure drop/resistance to airflow, taking longer to reach 2X the initial pressure drop while maintaining air quality through sustained MERV-A ratings. A $10 filter that lasts twice as long as a $5 filter provides a lot more value than meets the eye. In the long run, investing in a higher-quality air filter can save you money on replacements and maintenance costs.

It’s important to consider not just the upfront cost, but the overall value and performance of the air filter over time. By choosing a filter that offers both extended lifespan and superior air filtration, you can ensure that you get cleaner air in your building while also saving money in the process by incorporating the total cost of ownership (TCO) of the air filter in your planning.

Read more about high-quality air filters

To consult with an air filtration expert on the topics covered in this post or for further information, please use this contact form and an air filtration expert from Camfil Canada will answer any questions you may have.

About Camfil Canada Clean Air Solutions

For more than 60 years, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. Read more about Camfil Canada

##

Media Contact:

Phillip Ilijevski

Camfil Canada Inc.

T: 437-929-1161

-Air filtration expert Jon Holmes, Camfil Canada