A lower average pressure drop translates to significant energy savings by reducing the work required to move air. It also optimizes HVAC system performance. When comparing filters with the same design, the filter with lowest average pressure drop will last the longest, requiring less frequent replacements. It also contributes to better indoor air quality throughout the filter’s life. This article will explain the science behind pressure drops and will explain the benefits of prioritizing it.

Why Average Pressure Drop Matters: The Key to Superior Air Filtration

Air filters have very small holes that allow air to flow through with relative ease. As the filter collects dust, resistance to airflow increases. Once airflow reaches a certain pressure drop, it’s time to change the air filter.

It’s important to note that average pressure drop is a much more valuable measure than initial pressure drop. While a low initial pressure drop is desirable, it’s most important for the filter to maintain its effectiveness over its entire life. A filter that can sustain good airflow over its life without clogging will continue to collect dirt efficiently, allowing air to pass through with minimal resistance.

The misleading nature of the initial pressure drop

Using initial pressure drop as a measure of air filter performance and quality is not effective because it lacks real-life testing to determine how long a filter will actually last. Real-life testing allows us to assess a filter’s lifespan in various environments.

Standard air filter testing typically involves exposing the filter to atmospheric dust (ASHRAE dust), which is significantly larger than the particles the filter would encounter in actual conditions.

Air filter expert Berni Baier explains, “Filters are usually tested with extremely large dust particles, and they all perform similarly throughout that test. But it doesn’t accurately predict how long a filter will last because it does not replicate real-world conditions with the types of contaminants typically found in buildings and facilities.” He adds, “Camfil utilizes real-life scenarios so we can provide a realistic expectation: when you use this filter at a specific pressure drop, it is likely to last a certain amount of time, unlike simulations with simulated dust, which can be misleading.”

To illustrate this with another example, consider a car’s rated fuel efficiency, which might be 7.0 L/100 km. This rating is based on ideal conditions, like driving on a flat road. However, if you encounter hilly terrain, or you put the ‘pedal to the metal,’ your car will perform as well as a vehicle does in ideal conditions. The ASHRAE dust tests represent an ideal scenario with manageable dust.

How does lower resistance result in less energy required to maintain airflow?

The biggest energy user in any air handling system in a building is the air handling blower. The more the blower has to work, the more energy it consumes. If you have a filter that creates less resistance to airflow, the fan operates more easily, thereby using less energy.

This pertains to HVAC systems with variable-frequency drive (VFD)-controlled fans. A VFD-controlled fan measures the level of resistance and adjusts its speed accordingly, giving a consistent volume of air passing through the filter.

In contrast, a constant-speed fan runs at a fixed speed regardless of resistance. As airflow encounters increasing resistance, the fan struggles to maintain performance, leading to a clogged filter and diminished airflow. On the other hand, a VFD fan starts at a lower speed, and as more airflow is needed, it gradually increases its output until it reaches the maximum required volume.

Does consistent performance over time reduce maintenance and replacement frequency?

Not all air filters are created equal. One batch of air filters may have a pressure drop of 0.35 inches of water gauge (W.G.), while another batch may have a pressure drop of 0.33 inches. To ensure reliable performance, consistency in the efficiency of the media, its density, and type is important. If you install a filter, it should perform well even towards the end of its lifespan, not only when new.

Some companies do not test the media or any other aspects of the filters; they simply rely on the media manufacturer to provide the correct product. However, this could lead to receiving inferior batches of media. The pressure drop and loading curve of that filter could vary significantly, leading you to believe that the filter will last throughout its claimed lifespan of three months or so. But if you don’t regularly monitor it, you may find that it has clogged within a month, possibly causing blowouts and equipment failure.

It is crucial to depend on the manufacturer to supply the same type of media performance and quality. When filters are designed and manufactured with longevity in mind, you will experience fewer changeouts and reduced maintenance.

Understanding Air Filter Performance: Initial vs. Average Pressure Drop Explained

How is the initial pressure drop defined?

The initial pressure drop refers to the resistance that airflow experiences at a specific velocity. For example, if someone installs a filter in a system with a VFD-controlled fan that is initially running at 300 feet per minute, they may not realize that shortly after, the fan speed has increased to 500 feet per minute because of a change in activity level. Any testing should be conducted at the same velocity for accurate results.

How is the average pressure drop of an air filter defined?

The average pressure drop is the difference in pressure between point A and point B over a specified period.

There can be significant variations in average pressure drop depending on the application. For instance, in a university or college setting, if many students frequently use a meeting area during the day and it’s empty at other times, the air filter may not last as long as expected. This happens because of a higher combination of indoor and outdoor contaminant levels being generated, which are typically the biggest contributing factors to pressure drop.

The impact of pressure drop on a commercial or public building

In commercial or public buildings, the impact of pressure drop is notable. Many companies have employees who only work 2 or 3 days a week in the office, while the other days are spent working from home. However, if many of those employees return to the building full-time, the lifespan of the air filters may decrease due to increased internal contaminants.

Another significant factor affecting filter longevity is the type of activities taking place in neighbouring buildings. For example, if a building is located next to a sugar factory, the air filters may need to be replaced every month because of the pollutants from the adjacent facility. This issue is particularly pronounced in commercial applications located in industrial areas, where the presence of various manufacturing activities can greatly increase contaminants and drastically reduce filter life.

Case study on switching to high-quality filters with lower average pressure drop

Jon Holmes talks about a recent experience he had with a corporate customer, “I can’t mention the name, but it’s a global automotive company that switched to HiFlo ES filters.”

The results of the switch:

- They measured their energy consumption before and after the switch while keeping the volume of air the same. They had 38 HVAC units, each using 30 filters.

- With the previous filters, their Variable Frequency Drives (VFDs) ran at 92%, but with Hi Flo ES they were able to ramp down to 75% to supply the same volume of air.

- During their kaizen event, they found they saved 3.6 million kilowatt-hours per year, amounting to $173,000 in savings annually.

- This reduction also translates to 3,446 metric tons of CO2 emissions, which is equivalent to taking 50 cars off the road or providing enough electricity to power 336 homes.

Jon states, “I found it interesting because we used to have a campaign comparing filters to LED lights. Everyone has transitioned to LEDs these days, and I had some great stats about the costs—around $1.00 to $2.00 per square foot. The story of HiFlo ES filters shows that you can achieve the exact same kWh reduction as switching to LEDs from incandescent lights, but at one-tenth the investment.”

Energy Savings and Cost Benefits: How Lower Average Pressure Drop Translates to a better return on investment

Using filters with the lowest average pressure drop results in reduced energy consumption and lower operational costs over time. It also extends equipment life and causes less strain on HVAC systems, which leads to lower maintenance. All of this amounts to cost-effective investment, realizing savings over the filter’s lifespan and improved ROI.

Camfil advises that after switching to premium air filters, it takes about a year or two to realize savings.

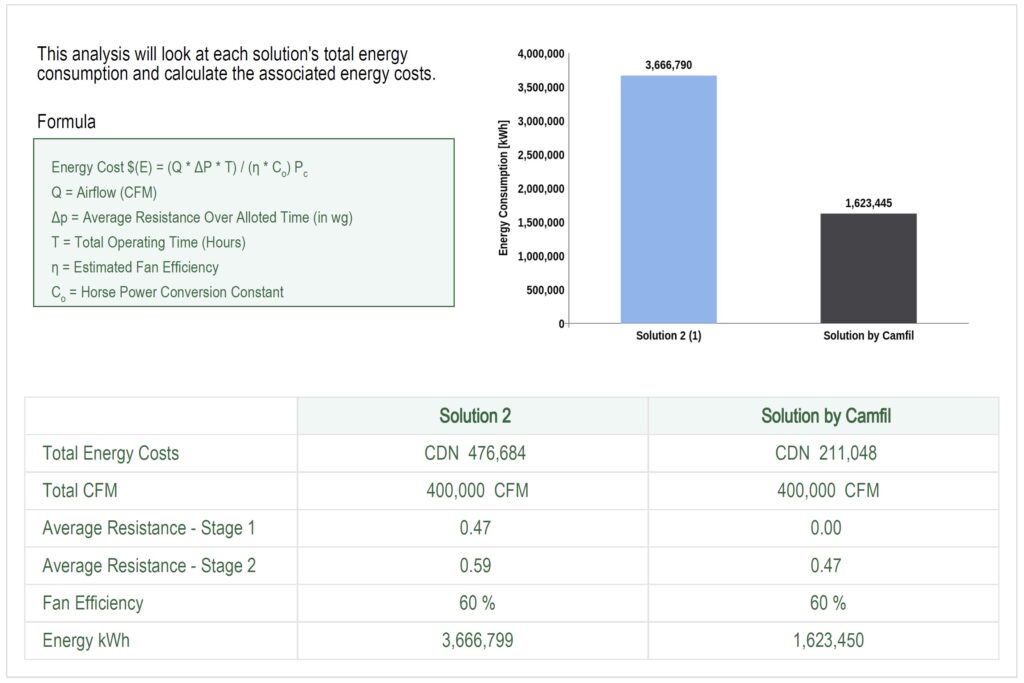

How much money can actually be saved? Here’s an example using the LCC software:

Life Cycle Costing Software for air filters

Regional conditions affecting air filtration in Canada

In Canadian coastal cities such as Vancouver and Victoria, the biggest issue affecting air filters is humidity because of cities’ proximity to the Pacific Ocean. If very high humidity is resulting in problems with your filter condition, it’s best to use media with wet-laid glass, such as Durafil® or Aeropac®.

In Toronto, Mississauga, Pickering, and other areas, the challenge for achieving good IAQ is from pollution from vehicles and industry. The very densely populated urban landscape of the GTA creates conditions such as heat islands that trap pollution and don’t allow for enough air circulation to dilute pollutant concentration. In this case, it’s best to use higher dust holding capacity filters such as the 30/30 Dual 9® and HiFlo ES® to reduce operational costs.

In Western and Central Canada, a serious challenge to air filtration is poplar fluff

In late spring and early summer, poplar fluff drifts through Calgary’s urban forest, while in Edmonton, it collects in parks and paths. In Metro Vancouver, white fluff floats in Surrey and the Tri-Cities, and black cottonwood trees thrive along the Fraser and Chilliwack rivers.

Camfil’s Jon Holmes states, “Poplar trees are a big issue in terms of clogging air filters, reducing airflow, and they are a potential fire hazard. The Dual 9 30/30 is a perfect solution because the poplar fluff lasts only four to six weeks, and they know approximately when that happens each year.” He adds, “I would recommend installing filters at the end of the poplar fluff season, which would be around the end of May or the beginning of June. This way, it will be new and effective after the fluff has gone. If you change the filter before that, you might have to replace it again in three to four weeks when it gets filled up.”

Hoarfrost and Shad Flies in Calgary and other Canadian cities

Hoarfrost can also be a challenge in winter in Calgary. During hoarfrost season, traditional gas-powered units (which lack a coil between sections) may not require a filter. Issues like shadflies in parts of Ontario and in Alberta and British Columbia can be a challenge to air filtration. An air filter expert may recommend certain types of filters to deal with hoarfrost and shadflies/mayflies.

Wildfires and air filtration

There have also been an increasing amount of wildfires in the past few years in Canada.

“British Columbia saw the most wildfires (in 2024) with 1,687, followed by Alberta (1,224). Estimated area burned was above the 10-year average in British Columbia, Yukon, Alberta, Northwest Territories, Saskatchewan, and Newfoundland and Labrador.” cwfis.cfs.nrcan.gc.ca/report

Carbon coupled with high-efficiency filters should be ready for installation to get rid of odours and fine, particulate matter from the smoke. Once the wildfires are contained, carbon-based filters can be removed to increase airflow.

Camfil’s Superior Solutions: 30/30 Dual 9, Hi-Flo, Hi-Flo ES

What are the features in terms of airflow and average pressure drop with the 30/30 dual 9?

The 30/30 Dual 9 filter uses dual-density media and lasts significantly longer than a standard filter. This is because it is designed to collect large particles in one section of the media and small particles in another, effectively performing two filtration tasks simultaneously.

As a result, the average pressure drop of a 30/30 Dual 9 is very low, allowing it to maintain efficiency for an extended period of time compared to a standard, pleated filter.

Pleat design is crucial because when they become clogged or bunched, airflow is restricted, reducing the filter’s lifespan. Hypothetically, if 50% of the pleats in a filter are blocked, its effective lifespan will be reduced by approximately 50% of its potential maximum.

The 30/30 Dual 9 features a radial pleat design with open U-shaped pleats. This design allows dirt to be collected throughout the media rather than having the pleats too close together.

The benefits of the Hi Flo ES

The Hi Flo ES features fiberglass-based media. Its key feature is tapered, V-shaped pockets. The V-shaped design ensures that the pockets remain separate. This allows for improved airflow between the pockets and maximizes the use of the filter media.

Camfil collaborates with media manufacturers to obtain a specific fibreglass loft that enhances performance. Additionally, the HiFlo ES features proprietary dual-density media, eliminating the need for a pre-filter.

What is a Durafil?

Camfil has improved the media on the Durafil filters. The Durafil features wet-laid glass, an inlet design, and a rigid frame, height-to-pleat spacing ratio, which is essential for maintaining effectiveness in challenging conditions. It consumes over 35% less energy than typical V-bed filters. The enhanced strength offers protection against blowouts and minimizes the risk of media tearing and related issues.

What are the key benefits of switching to a lower average pressure drop filter?

It results in less waste, reduced energy costs, and extends the longevity of the filter.

How can I determine, using pressure drop, when my air filters should be changed?

To determine when to change your air filters using pressure drop, ASHRAE recommends following these steps:

● Baseline Measurement & Monitoring: Measure the initial pressure drop and track changes to assess filter performance. ASHRAE Standard 52.2-2017 provides testing guidelines.

● Visual Inspection: Regularly check for excessive dirt buildup or damage; replace filters when they reach their maximum pressure drop.

By monitoring pressure drop and considering these factors, you can effectively determine when to change your air filters for optimal performance.

ASHRAE states, “Higher efficiency filters can increase pressure drop, affecting airflow and energy use, so system capabilities should be considered.”

It’s crucial to use air filters designed specifically to provide the lowest average pressure drop with the highest MERV rating.

Pressure gauge or Magnehelic Gauge

When testing competitor filters, use a pressure gauge. This gauge helps you measure pressure and can identify negative impacts within the HVAC system. There may be instances where you believe the fan is operating at a certain speed based on data from the building automation system. However, when you check the gauge, it might indicate a pressure drop that is twice as high as expected.

Upgrade Your Air Filtration Strategy with Camfil Today:

Switching to Camfil filters with a lower average pressure drop provides benefits such as improved energy efficiency and cost savings.

To consider the switch, take the following steps: schedule a Site Survey for personalized energy savings consultation, request a demo to experience our solutions on your site, or contact a local expert for regional support.

FAQs:

What is the difference between initial pressure drop and average pressure drop?

The initial pressure drop refers to the resistance an air filter creates when first installed, while the average pressure drop is the sustained resistance over the filter’s lifespan. A lower average pressure drop means less energy consumption and better overall performance.

Why is a lower average pressure drop important for HVAC systems?

A lower average pressure drop ensures consistent airflow, reduces energy usage, minimizes wear on HVAC components, and extends the filter’s lifespan—leading to significant cost savings over time.

How do Camfil air filters help improve energy efficiency?

Camfil filters are designed to maintain a low average pressure drop, which reduces the work required by HVAC systems, thereby saving energy and reducing operational costs.

Can I see real-world data or case studies on Camfil’s filter performance?

Yes, Camfil’s website provides detailed case studies and research reports, including insights from the CamLab and various testimonial videos. Camfil.ca

How can I determine if it’s time to replace my air filters?

Look for signs such as increased energy consumption, reduced airflow, or reaching the manufacturer’s recommended pressure drop levels.

Would you like to improve the air quality in your building today? Start by contacting Camfil for a complimentary site survey for your commercial building, public building, or other facility. Use this contact form

About Camfil Canada Clean Air Solutions

For more than 60 years, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. Read more about Camfil Canada

##

Sources:

With information from air filter experts Berni Baier and Jon Holmes

Media Contact:

Phillip Ilijevski

Camfil Canada Inc.

T: 437-929-1161

Sources:

ASHRAE

EPA

ENVIRONMENT CANADA